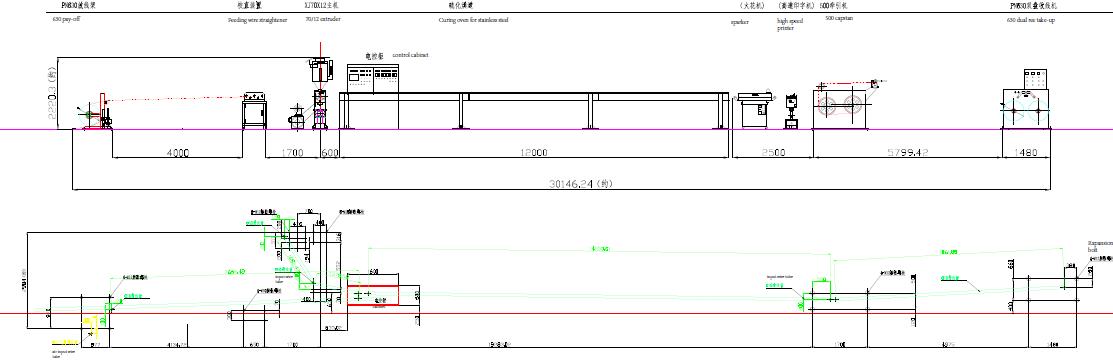

70/12 Silicon Rubber Extrusion Line Machine.

1.Use:

The unit is used for extruding silicone rubber core insulation and continuous vulcanization. The operation of the whole unit is stable and reliable, the operation of each component is synchronous, and the control system is reliable, advanced and applicable. The machine is suitable for extruding silicone rubber raw material.

Ningbo Capstian Technology Co.,Ltd.

Ningbo Capstian Technology Co.,Ltd.