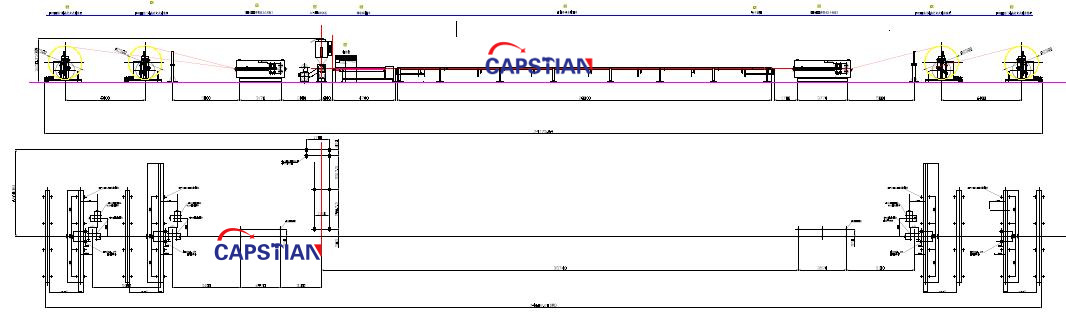

SJ200/25 Cable Coated Production Line / Cable Sheathing Machine / Cable Insulation Jacket Production Line /

Cable Extrusion Line / Cable Sheath Jacket Machine.

1.Application:

This unit is suitable for wrapping PVC, PE, XLPE, low smoke and halogen-free thermoplastic cable materials by hot extrusion.

It use double pay-off and double take-up structure.

Electrical control characteristics

----The control system is based on PLC, and PLC sends out control instructions. PLC completes the single action or linkage control requirements of

the production line, and realizes the monitoring of the operation status and operation parameters of the production line.

----The software package of control system has the function of uploading and downloading all kinds of cable production process formula, and can

download the corresponding control formula parameters according to the cable parameters to be processed.

----The control system has the function of recording and printing the operation status and alarm status of production line equipment.

----The constant tension control mode is adopted for front and rear traction to ensure the constant Online Tension of double traction.

The tension can be set and modified manually.

Ningbo Capstian Technology Co.,Ltd.

Ningbo Capstian Technology Co.,Ltd.