|

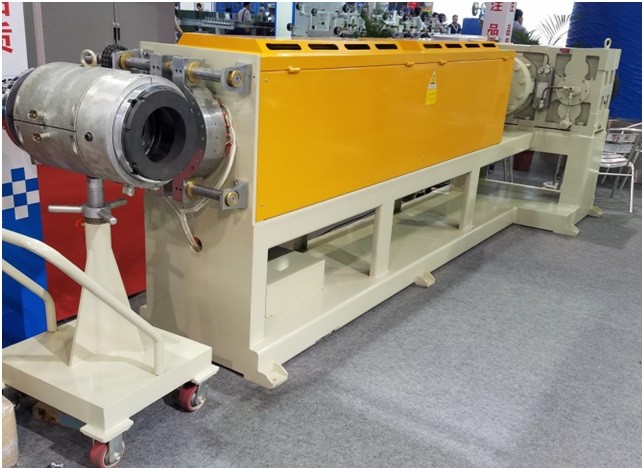

Structure type: national standard steel

frame, base plane finish milling, gear box, Jiangyin cast steel square hard

tooth surface precision gear box

Screw diameter 50 mm, gear material 20CrMo

alloy material, hardening wear-resistant heat treatment

Length diameter ratio 36:1, heating type,

precision cast aluminum heater with air groove

Compression ratio PVC:2.6 ~2.9 / PE: 2.9 ~

3.4 number of heating sections and temperature control of 4 sections of

fuselage

Speed range: 10 ~ 100RPM temperature control

brand RKC microcomputer intelligent temperature control meter

Screw material 38CrMoAlA temperature control

principle temperature control meter set temperature, heating and cooling work

alternately

Screw hard plating screw hv930 ~ 945 /

barrel hv910 ~ 925, temperature control accuracy ± 1 ℃

Screw plating, screw surface hard chromium

plating polishing treatment, galvanic couple type k-tape

The driving power is 15kw / 5HP 3-phase 380V

Screw barrel cooling, circulating water cooling,

screw inlet and gear box heating power: 22kw

The machine clamp type is screw thread type

and single side half clamp type, with quick disassembly and glue output of

50kg / hr

Screw cylinder shield high quality SUS304

bright stainless steel machine quality

2. Main features

stable glue output: screw optimized design,

wear resistance, no glue, durable, stable glue output ■ accurate temperature

control: PID temperature automatic control, small temperature fluctuation,

temperature control accuracy ± 0.5 ℃

uniform foaming: equipped with special

foaming screw and slow pressing groove design, it can avoid the temperature

rise of the barrel caused by the rapid pressing of the rubber material during

the extrusion process, effectively prevent the decomposition and aging of the

rubber material, and the foaming degree is uniform and stable in the foaming

extrusion process ■ the flow channel is smooth: all the pipes that the rubber

material passes through are designed smoothly, and there is no pressing step

in the flow channel pipe to prevent the rubber from moving forward, To

prevent temperature fluctuation caused by rubber retention, resulting in

rubber aging and decomposition

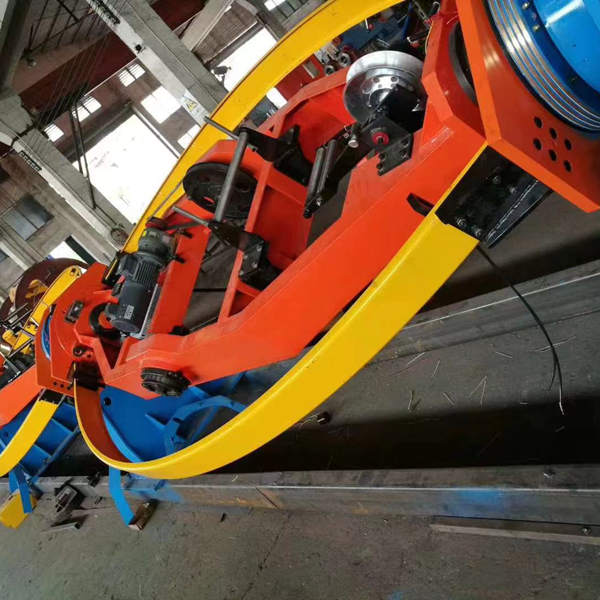

centralized piping and wiring: the

circulating cooling water pipes and wire circuits on the main engine are

arranged in a centralized way, and only the inlet and outlet interfaces of

water pipes and power supply interfaces are reserved, which is convenient for

installation and maintenance ■ the head level remains unchanged: the head

support frame adopts small clearance precision machining of rotating hinge,

the opening and closing of the head flange does not damage the adjusted head

level, and the product has high concentricity.

|

Ningbo Capstian Technology Co.,Ltd.

Ningbo Capstian Technology Co.,Ltd.