|

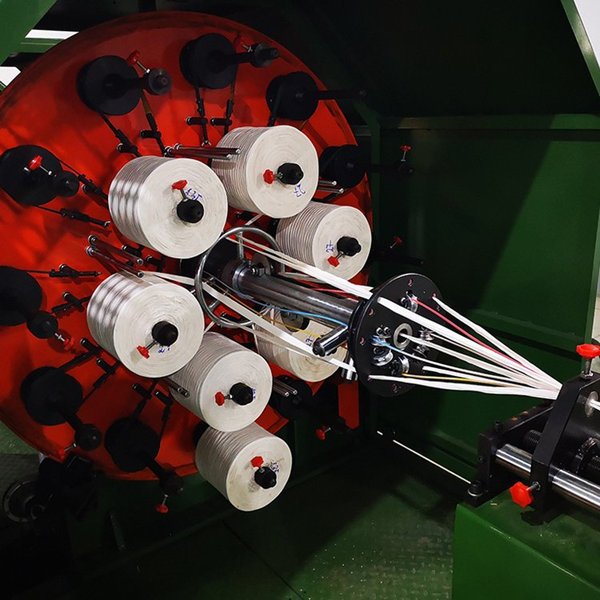

4.1.6 cradle frame structure: the cradle adopts pneumatic center to tighten and

loosen the reel, and has pneumatic locking device to prevent the reel from

throwing out. The wire tray bracket at the bottom of the cradle is safe and

convenient for loading and unloading the wire tray. After welding, the steel

cradle frame is tempered as a whole to eliminate the stress, enhance the

mechanical performance and do not deform. After finishing by the boring

machine as a whole, the accuracy is effectively guaranteed.

4.17 tension form: pay off tension is provided by the friction between tension

friction plate and tension belt, and the tension can be adjusted manually.

4.1.8routing

mode: the wire in the stranding cage is routed through the outside of the

stranding bow, and the guide roller group is set in the cradle. The wire is

put into the stranding bow through the guide roller group, and the stranding

bow is equipped with multiple groups of wire passing brackets. The wire

passing bracket is made of aluminum alloy material, and the inner part of the

bracket is inlaid with wear-resistant alloy wire passing die and wire

stabilizing idler. The wire is directly put into the distributing tray

through the wire passing bracket. The whole threading process is reasonably

designed and the wiring is stable The wire is stable and not easy to scratch.

4.1.9 bearing and lubrication system: the winch cage bearing adopts the brand of

"German SFAG", which is suitable for high-speed operation. The

bearing seat is forced to supply oil for lubrication through the oil pump

motor inside, and the lubricating oil cooling device is set outside, which

has dual functions of lubrication and cooling to ensure stable operation

4.1.10 Winch: the winch is made of special steel, with high flexibility and strong

bearing capacity. It is installed on the support of rhombic bow frame, and

dynamic balance correction is performed after assembly. Each winch is

equipped with butterfly pneumatic brake device.

4.1.11 supports: the supports at both ends of each section of the hinge cage are

gray iron castings with EPC process, which can fully absorb vibration, reduce

noise and have beautiful appearance.

4.1.12 driving mode: the power of the main engine relies on a through shaft to drive

each section of the winch through the toothed belt, the torque is uniform,

and the winch does not bear the torque, so as to fully avoid the cracking of

the winch. Toothed belt transmission can effectively avoid loss of rotation.

4.1.13 base: the hinge cage is installed on the overall welding base. The base is

formed by welding high-quality steel plate and rectangular pipe, and then

processed by large gantry milling machine. It has high levelness and improves

the operation stability.

4.1.14 filling frame: six groups of filling rope pay off frames are set at the front

bracket of the winch cage, and the filling device rotates synchronously with

the winch cage. Filling rope size: 160mm. (fill size to be provided by

customer, diameter and length)

4.1.18

distribution board: the distribution board is connected with the main

machine, with 12 holes evenly distributed, wear-resistant alloy wire sleeve

embedded in the hole, and has the function of breaking and stopping with

throwing block. After breaking, the whole machine will stop and brake

automatically, and the breaking information will be displayed on the

man-machine interface.

4.1.15 the protective cover adopts the closed sliding door structure, and the

working light is set inside the cover, which has the function of door opening

and parking, so as to improve the protection level. Emergency stop, inching

and other buttons are set outside the shield for easy operation.

4.1.16 the host computer is operated by human interface touch screen and managed by

PLC

|

Ningbo Capstian Technology Co.,Ltd.

Ningbo Capstian Technology Co.,Ltd.