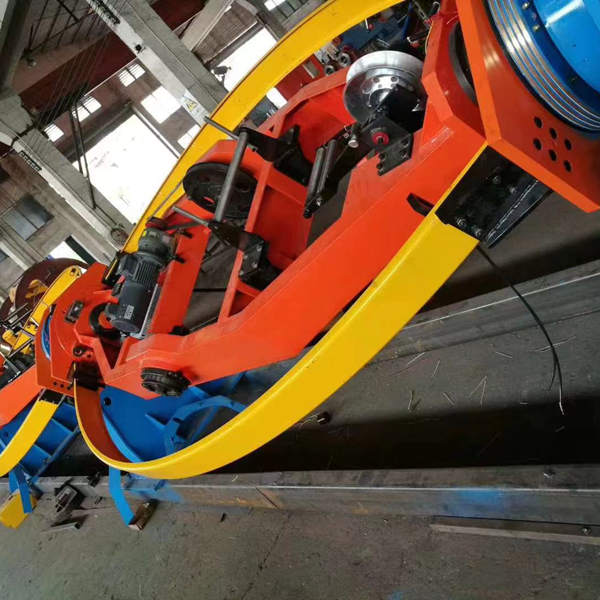

630/1+6+12+18 Planetary Strander With 100% Back-twist.

1. Use:

This equipment is mainly used for steel wire armor, and can also be used for control cable, signal cable, small size plastic cable and bare copper, bare aluminum wire stranding.

Control Cables Assembly with Back Twist.

Signal Cables Assembly with Back Twist.

Insulated Cables Assembly such as Robot Cables with Back Twist.

Ningbo Capstian Technology Co.,Ltd.

Ningbo Capstian Technology Co.,Ltd.