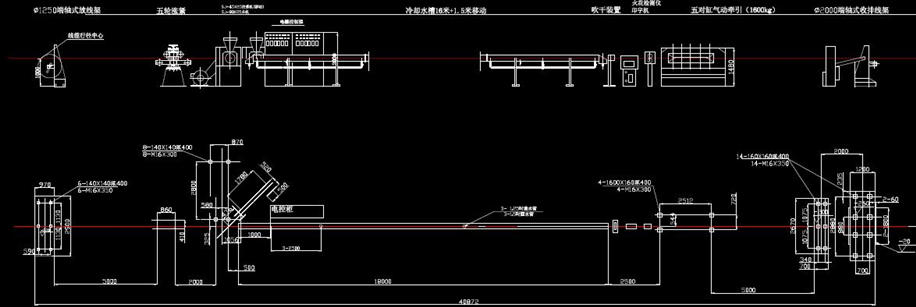

SJ90+45 Cable Extruder Production Line Machine.

1.Use:

This unit is suitable for covering the sheath of the wires and cables by hot extrusion method for thermoplastic cables such as PVC, PE, XLPE, low smoke and halogen-free.

It has the advantages of fast production efficiency, durability, practicality and low price. It adopts the first international technology and internationally famous brand electrical appliances.

Ningbo Capstian Technology Co.,Ltd.

Ningbo Capstian Technology Co.,Ltd.