|

4.2.3 full arterial protection

4.2.4 large bearing protection 1 high

temperature alarm

4.2.5 large bearing protection 2 insufficient

oil supply alarm

4.2.6 threading mode: wiring inside the

cylinder

4.2.7 form of tension mechanical friction

tension

4.2.8 installation mode: end shaft type,

clamping and loosening the wire coil by electric wrench, internal mechanical

locking, safe and stable, not easy to throw out the outlet plate, and

convenient to load and unload the wire coil. The wire reel is lifted into the

cradle with the aid of the aerial vehicle in the workshop.

4.2.9 form of tension in cradle: mechanical

friction tension is adopted, and the tension is manually adjusted.

4.2.10 the pay off frame is in the form of

integral bending and welding. After NC cutting and bending of raw materials,

the integral assembly welding is carried out, and then the internal stress is

eliminated through annealing treatment, and the overall mechanical strength

is enhanced. It is made of high precision, high mechanical strength and

durability.

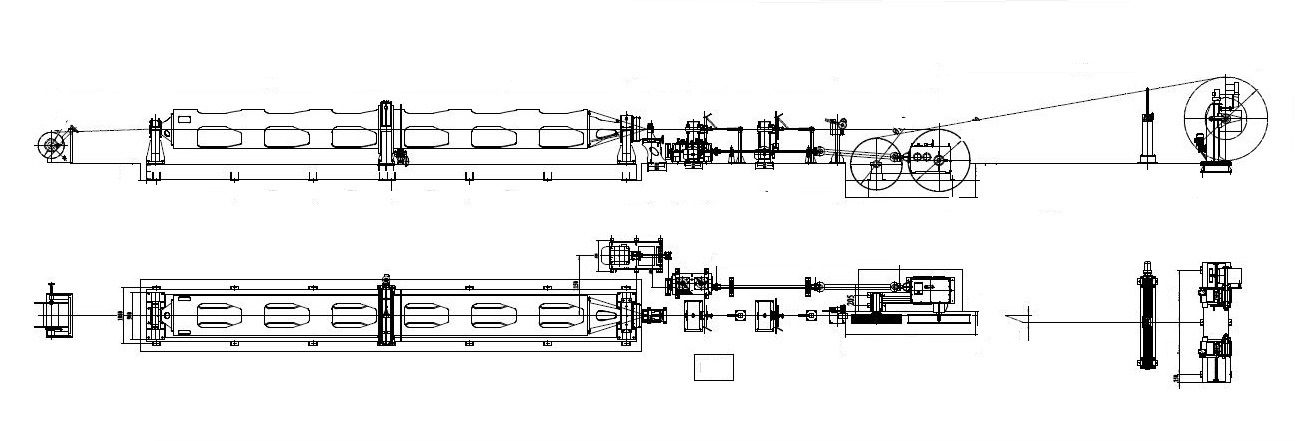

4.2.11 the cylinder body adopts 3 + 3

two-stage, whole pipe bearing structure, double row roller self-aligning

bearing support is used in the support frame of pay off inlet and outlet end;

two groups of large bearing support are used in the middle; oil pump motor is

used for oil supply, thin oil lubrication, labyrinth seal, with dual

functions of lubrication and cooling, oil storage in bearing seat chamber, no

need for single oil tank, small floor area and clean working condition.

4.2.12 the base of the main engine is an

integral welded part with one-stage structure. The plane is processed by

large-scale machine tool to improve the overall stability.

4.2.13 the double automatic shutdown

protection function of "high temperature early warning and flow early

warning" is added to the large bearing group to avoid damage to other

hardware caused by operation in bad condition and get timely maintenance.

4.2.14 the cylinder body is made of thick

walled steel pipe. Annealing treatment is conducted before processing to

eliminate internal stress, and dynamic balance correction is conducted after

overall processing.

4.2.15 main engine braking: butterfly type

pneumatic braking device is adopted to ensure safe and reliable braking.

4.2.16 the main engine adopts internal wiring

mode, equipped with multiple wear-resistant thread nozzles or guide wheels

and guide roller groups, so as to make the wiring more smooth, no bending, no

scratch and no groove jumping.

4.2.17 the rear support seat of the main

engine, the large bearing pedestal at the middle and outlet end are all made

of gray iron castings with EPC process, which can fully absorb vibration,

reduce noise and have a beautiful appearance.

4.2.18 the new type of front drive is adopted

for the main engine, and the cylinder body does not bear torque, so as to

fully avoid cylinder cracking. Toothed belt transmission can effectively

avoid loss of rotation and ensure stable and even pitch.

4.2.19 the protective cover of the main engine

adopts the push-pull structure, and the far-infrared personnel close to the parking

protection is set at the operation side of the main engine to improve the

safety level of the equipment operation.

4.2.20 the front end of the whole machine is

equipped with 6 pre deformers and pre twisted pitch.

4.2.21 it is equipped with automatic pulse

type wire breaking stop protection device, which can stop and brake in time

after the broken wire and wire are used

|

Ningbo Capstian Technology Co.,Ltd.

Ningbo Capstian Technology Co.,Ltd.