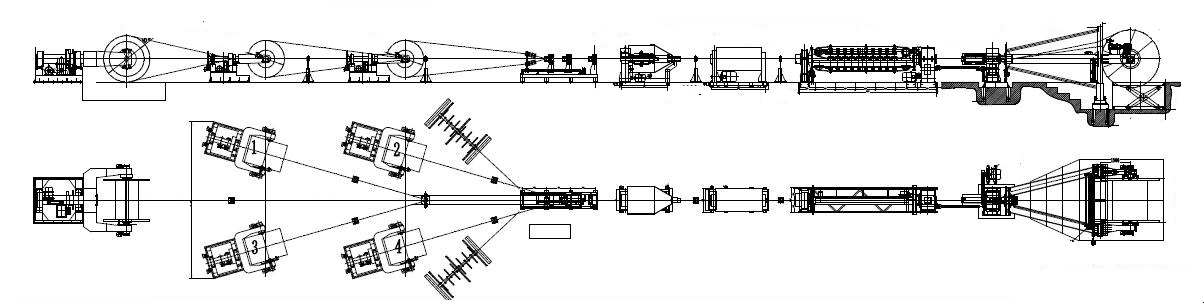

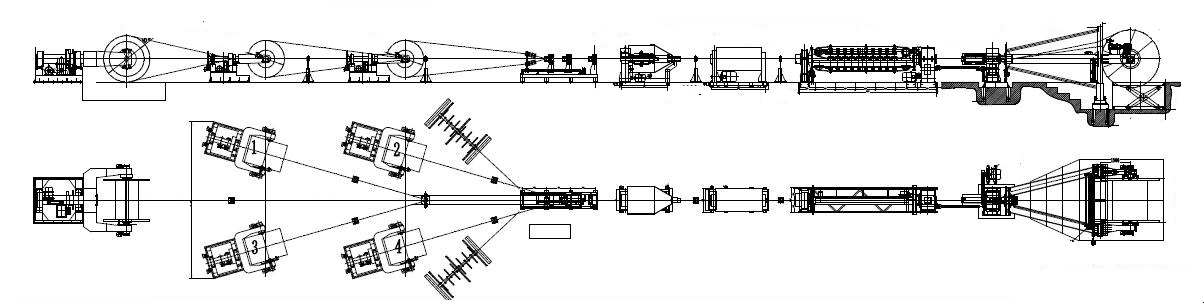

2500mm Drum Twister With 4x1600mm and 1x2500mm Pay-off.

1.Use:

Drum Twister Type cabling machine is used for laying-up of large section, long length power cables. The line is for laying-up of pre-spiral or non-pre-spiral cable cores and Milliken cable. The line is used for steel wires armoring of power cables.

The machine is operated through IHM, operation and rotation of each unit are coordinated by programmable control. The electric control system is advanced and reliable.

5.Electrical control system

|

5.1. The operation and operation of

the whole set of units are completed by an independent main control cabinet,

which is set separately with power cabinet. In order to facilitate operation

of each unit, each unit is equipped with separate operation sub cabinet or

button. The main control cabinet is controlled by touch screen operation PLC

to control all parameters of each unit during cable forming process, and can

display the running speed and operation parameters of each unit in real time,

so as to modify and adjust the operation parameters of each unit in time.

5.2. The power supply is three wire

and five phase system 380V( ± 10%)50HZ

5.3. Total installed power ≤250KW

5.4. Working principle of

electrical equipment: all drive motors are equipped with encoder, encoder

feedback is operated in control system, and the whole machine is controlled

by PLC uniformly: frequency converter, brake unit, air press actuator, etc.

are operated to start, jog and stop normally to ensure stable synchronous

performance

|

6. Safety protection system

|

6.1. Safety protection: the machine has many safety protection, and

can make corresponding protection measures in case of failure or failure to

meet the normal operation of equipment and display the fault point on the

screen of the main control cabinet in time, so as to facilitate the operators

to make timely and accurate judgment and effective treatment scheme.

6.2. Protection of main drive system and motors and fans

6.3. Horizontal limit protection of each receiving and setting out

frame

6.4. Over trip protection of line arrangement

6.5. Meter meter and meter parking protection

6.6. Protection against air pressure under pressure

6.7. Machine shutdown protection

6.8. Breaking and finishing protection of wrapping belt

6.9. Open protection around the protective cover

6.10. Limit protection of hydraulic lifting platform

|

Ningbo Capstian Technology Co.,Ltd.

Ningbo Capstian Technology Co.,Ltd.