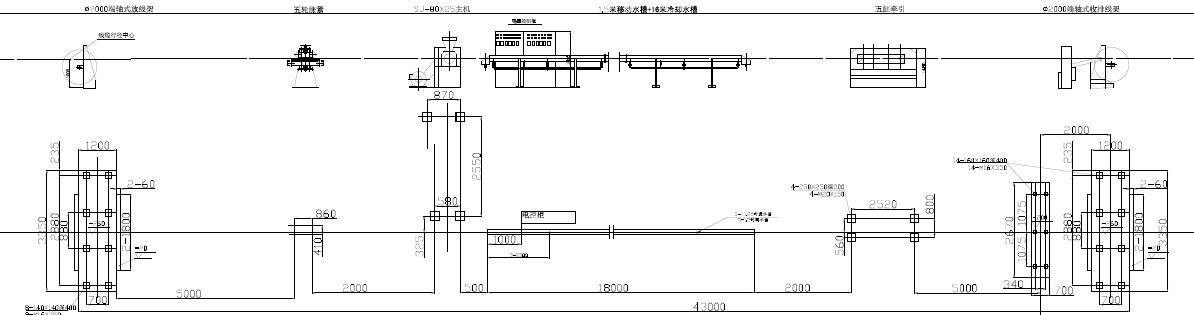

80mm Power Cable Sheath Extruder Line Machines.

1. Use:

This unit is suitable for wrapping PVC, PE, XLPE, low smoke and halogen-free thermoplastic cable materials by hot extrusion.

Machine Characteristic

Special Screw Design:

Special output flow path designed for melted plastic guarantee high quality of extrusion.

Heating tube technology has been used in screw design,It can strengthen cutting and also avoid decomposing by overheat. Accordingly the melting of plastic can be increased in order to obtain extrusion of plastic in high speed.

High Precision Temperature Control System

Perfect electric control system

Frequency converter:Siemens.

Touch screen: Siemens touch screen

PLC :Siemens.

Motor: Siemens frequency conversion AC motor.

Testing equipment: OD tester UK proton , Hetai; spark tester, UK proton.

Temperature controller: Japan RKC.

Bearing: NSK.

Electric components:Schneider brand.

Ningbo Capstian Technology Co.,Ltd.

Ningbo Capstian Technology Co.,Ltd.