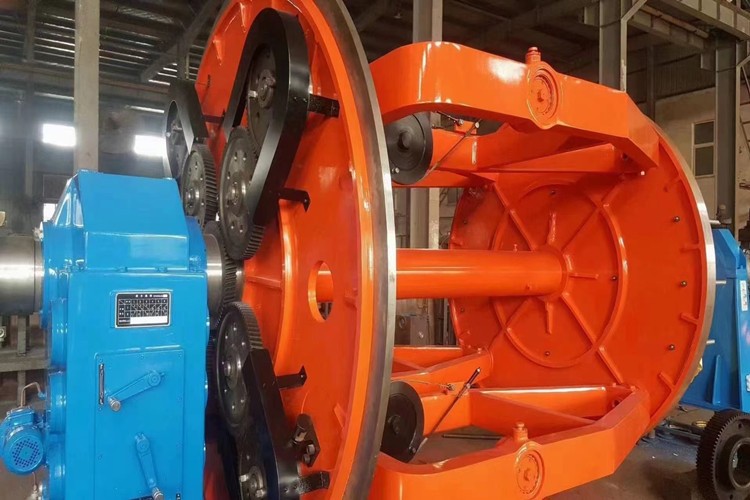

Planetary Type 1000/3 Bobbin Cable Laying-up Machine / Core Laying-up Machine / Cradle Laying-up Machine

Power Cable Twist Machine

1. Application:

-

The Laying up Machine is used for cabling the multi core ( 3-4 ), rubber cables, plastic power cables, telephone cables, control cables, PVC cables, XLPE cables with or without steel armouring, mining cables, low and medium low voltage power cables.

-

Stranding the round cables, sector shaped cables with back twist or without back twist.

-

Planetary Laying-up Machine is designed with 3 / 1+3 / 1+1+3 / 3+3 Bobbin Cage.

-

Bobbin: 800 mm, 1000 mm, 1250 mm, 1600 mm DIN 46391 Standard / Modified.

-

Core laying up machine, main shaft is supported with roller bearings.

-

Highly productive laying up process with low energy consumption. 1+1+3 / 1000 mm Planetary Laying-up Machine Max. Rotation Speed ( rpm ) is 21 RPM.

-

Rigid and Planetary Types.

-

PLC Equipped.

-

We also customise this cradle type cabling machine in accordance with customers’ requirements.

-

7. Main parts brand:

|

7.1

|

Bearing brand

|

(HRB.)

|

|

7.2

|

Low voltage appliance

brand

|

(Schneider/Chint)

|

|

7.3

|

Brand of pneumatic

component

|

(AIRTAC)

|

|

7.4

|

Brand of main drive motor

|

(JIANGHUAI)

|

|

7.5

|

Take-up motor brand

|

(JIANGHUAI)

|

|

7.6

|

Frequency conversion

controller

|

(INOVANCE)

|

8. Document with

machine

|

8.1

|

Use Manual

|

1 set

|

|

8.2

|

Foundation diagram

|

1 set

|

|

8.3

|

Overall diagram

|

1 set

|

|

8.4

|

Electrical drawing

|

1 set

|

|

8.5

|

Gas circuit layout

|

1 set

|

5. Air source requirement:

9.1. Air pressure: 0.6MPa

9.2. Gas volume: 1.8m ³/ min

9.3.The compressed air shall be dry and free of impurities and dust.

2. Main technical parameters

|

2.1

|

inter line dia

|

Φ6-Φ20 mm

|

|

2.2

|

Strand cage max rotation speed

|

13.9-33.1r/min

|

|

2.3

|

Max lay-up diameter

|

Φ60mm

|

|

2.4

|

Lay-up pitch

|

180~3200mm

|

|

2.5

|

Taping head

|

419r/min

|

|

2.6

|

Taping pitch

|

14.3-236.3mm

|

|

2.7

|

Traction line max speed

|

3.8-32m/min

|

|

2.8

|

Capstan force

|

Φ2000mm

|

|

2.9

|

Cage motor power

|

37kw(AC)

|

|

2.10

|

Pay-off bobbin size in cage

|

PN1000

|

|

2.11

|

Central Pay-off bobbin size

|

PN800-PN1250

|

|

2.12

|

Take-up bobbin size

|

PN1250- PN2500

|

|

2.13

|

Take-up motor power

|

5.5kw (AC)

|

|

2.14

|

Machine high

|

1000mm

|

Φ1000/3 bobbin stranding cage

4.2.1 Speed range of cage: 13.9-33.1r/min

4.2.2 Max single wire diameter: 20mm

4.2.3 Applicable reel: PN1000

4.2.4 Main cage speed level: 6 class,

with positive and negative idling

4.2.5 The main winch cage is composed of

four disc winch cage frame, main engine gearbox, tug, base, filling rope

paying off frame, etc.

4.2.6 The main winch cage is of parallel structure and has the function

of untwisting and twisting circular wires. Planetary gear set is used to drive

the untwisting. The design of the untwisting mechanism is reasonable and the

strength is high.

4.2.7 The winch gearbox adopts hard tooth surface grinding gear, and the

oil pump motor is forced to spray lubrication. The six-stage variable speed

design of the main engine box has positive and negative neutral positions. The

unit adopts ground shaft drive and the coupling adopts sprocket coupling.

4.2.8 The pay off frame in the stranding cage is of end shaft structure,

manual clamping reel, mechanical locking device and adjustable mechanical

friction tension device.

4.2.9 The front support plate of the cage is supported by supporting

wheels, and the tug is placed on the plane track and adjusted by screw rod.

4.2.10 The main engine adopts a large-diameter butterfly pneumatic brake

device, which is equipped with multiple groups of air brake, with high braking

efficiency.

4.2.11 the front support plate of the main engine is equipped with

multiple groups of 200 × 250mm filling frame

Ningbo Capstian Technology Co.,Ltd.

Ningbo Capstian Technology Co.,Ltd.