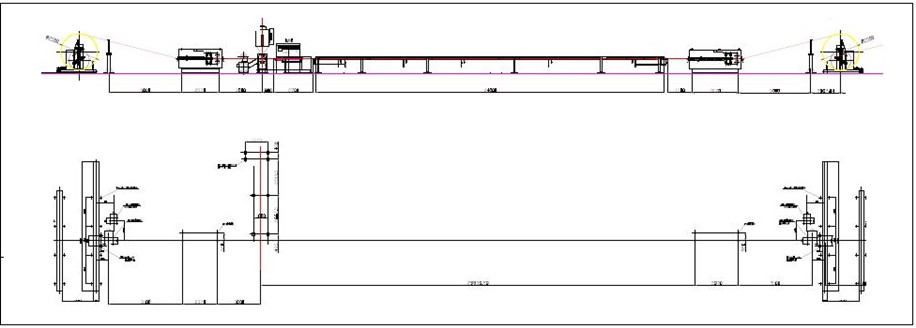

SJ150/25 Cable and Wire Extrusion Line Machines.

1.Use:

The unit is suitable for sheathing wire and cable by hot extrusion of thermoplastic cable materials such as polyvinyl chloride(PVC), low-smoke and halogen-free.

Wire and cable extruder is used for hot extrusion of polyethylene, PVC, etc. in wire and cable factories to insulate wire cores or protect cables. The whole machine is composed of pay off frame, main extruder, cooling water tank, dryer, printer, winch, coiling and finishing machine, temperature control electrical operation cabinet, etc.

Our wire and cable extrusion lines are famous for their high level of productivity and flexibility. They provide you with the most modern and latest software technology and high-quality corrosion-resistant components.

Ningbo Capstian Technology Co.,Ltd.

Ningbo Capstian Technology Co.,Ltd.