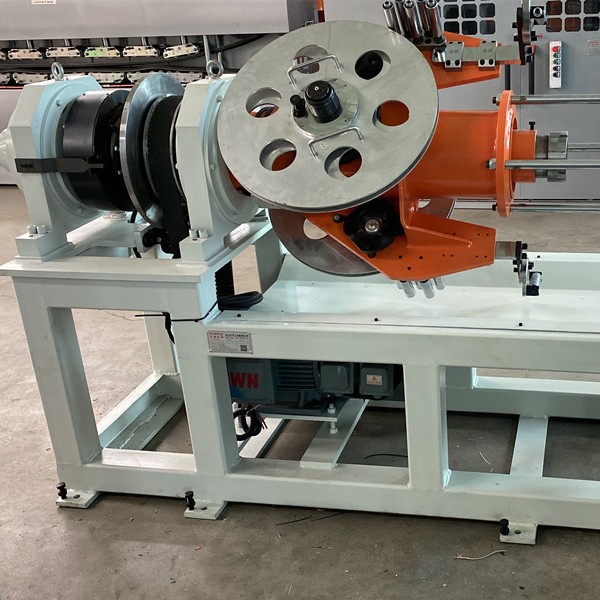

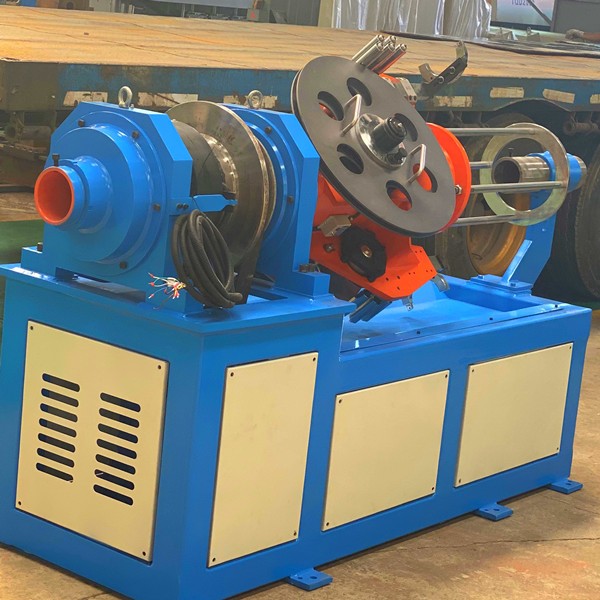

600 Tangent Type High Speed Double Head Taping Machine

1.Use:

It is mainly used for auxiliary machinery of cable and wire manufacturing machinery. For example, the winding of non-woven fabric, aluminum foil, film and other materials of frame winch and cable forming machine.

4.4.1

Taping form

Tangent form

4.4.2

Taking reel size

Φ600×φ80×(20-60)mm

4.4.3

Taping head max rotation speed

650rpm

4.4.4

Taping head pitch

Stepless adjustable

4.4.5

Pad qty

2 pcs

4.4.5

Motor power

11kw (AC variable frequency motor)

4.4.6 tape materials: polyester tape,

non-woven fabric, aluminum plastic composite tape, glass cloth, semi

conductive cloth, etc.

4.4.7 the wrapping machine is operated

through the touch screen of human-machine interface, and the PLC is used to

coordinate and control the start, stop, inching and other operations, so as

to ensure the synchronization of each unit in any running state.

4.4.8 the head structure of the wrapping

machine is a half cut type, which is driven by AC variable frequency motor

independently. The driving motor has built-in encoder. The encoder runs in

the closed-loop control system, and the wrapping machine has left-right

wrapping function.

4.4.9 the tape is loaded by the chuck.

The chuck is a quick open structure with mechanical locking function to

prevent the tape from being thrown out. The aluminum chuck is light and easy

to operate.

4.4.10 mechanical friction control of

wrapping tension. It has mechanical tension feedback function to ensure

constant tension from full plate to shallow plate.

4.4.11 brake system: the winding brake is

controlled by the air brake, frequency converter, brake resistance, etc.

through the unified coordination of PLC to complete the braking process. The

whole braking process is synchronized with the whole machine to ensure the

stability of pitch.

4.4.12 broken belt parking: it has the

function of pulse vector detection broken belt parking. The status of broken

belt and used belt can be monitored and alarmed, and the whole machine can be

braked.

4.4.13 safety protection cover: the box

type fully enclosed sliding door protection cover is adopted. The cover has

the function of opening and shutting down, with observation window and

working light inside

Ningbo Capstian Technology Co.,Ltd.

Ningbo Capstian Technology Co.,Ltd.