SJ90/25 Flat Wire Extruding Machines.

1.Use:

This

unit is suitable for coating the wire and cable with thermoplastic cable

materials such as polyvinyl chloride, polyethylene, PE, XLPE, low-smoke and

halogen-free by hot extrusion.

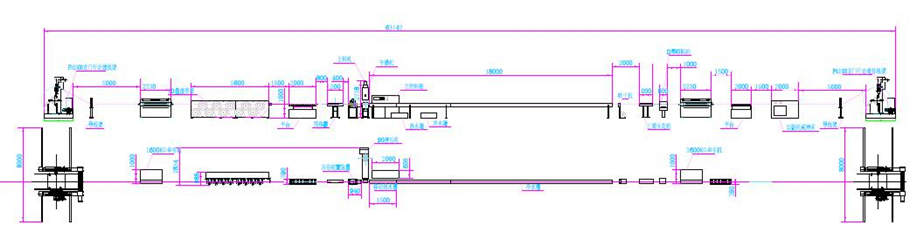

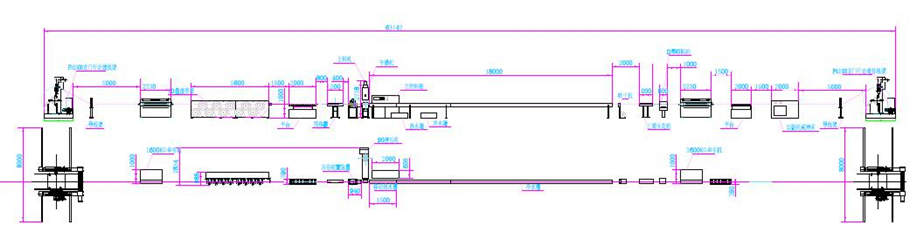

Flat cable/Ribbon cable extruder production line

1. Adopt custom head

2. Inveter control

3. Automatically monitor and adjust wire width

Application:

This extrusion line is applied to producing UL2468, 2651, 2678 and other computer flexible flat cables.

Characteristics:

This extrusion line adopts non-adjustable crosshead and special accumulator for flexible flat cable. The inverter control solves the problem of uneven thickness and wire tension, and prevents the copper wire from retreating after being cut. The equipped outside diameter controller helps monitor and adjust the outside diameter of the cable.

|

4.7.1

|

Screw diameter

|

φ90mm

|

|

4.7.2

|

Screw length to diameter ratio

|

25:1

|

|

4.7.3

|

Screw type

|

One high-efficiency double BM+ mixing

custom screw and one low-smoke and halogen-free special screw

|

|

4.7.4

|

Screw speed

|

80r/min

|

|

4.7.5

|

Glue amount (MAX)

|

PVC:280kg/h

|

|

4.7.6

|

main motor power

|

90 kW AC motor, Shenzhen Sinee

variable frequency speed regulation system control

|

|

4.7.7

|

Screw material: 38CrMoALA, surface

nitriding treatment, nitriding depth 0.5-0.8mm, surface hardness ≥ HV840

Barrel material: 38CrMoALA, surface

nitriding treatment, nitriding depth 0.5-0.8mm, surface hardness ≥HV1000

|

|

4.7.8

|

Screw cooling: water cooling

|

|

4.7.9

|

The temperature controller adopts

intelligent electronic display calculus temperature controller, the

temperature can be automatically adjusted between 0-399℃,

and the temperature control accuracy is ±2℃

|

|

4.7.10

|

Number of temperature control sections:

one section of the machine head, one section of the eye mold, one section of

the machine head lock, five sections of the barrel, cast aluminum heating

ring and five DF series axial cooling fans alternately running

|

|

4.7.11

|

The body adopts electric heating, and

the cast aluminum heating ring has good heat preservation performance

|

|

4.7.12

|

Head: Huff clamp, easy to operate

|

|

4.7.12

|

Gearbox: All gears are quenched and tempered with 40Cr, the tooth

surface is high-frequency quenched and the surface hardness is HRC50-55, the

shaft is quenched and tempered with 45# steel, the box is made of cast iron,

the gear is grinded with helical gears, gearbox and screw Adopting spline

connection, one-way roller thrust bearing

|

4.8

Extruder jacket head(Φ70mm and flat copper belt head)

|

4.8.1

|

Structure: adjustable head,

right-angle round structure

|

|

4.8.2

|

Heating form: cast aluminum heating

|

|

4.8.3

|

Scope of application: the maximum

diameter of the die sleeve is φ65mm, the maximum diameter of the extrusion

die core is φ60mm and the special die head for bronze flat wire

|

|

4.8.4

|

Material of machine head: surface

nitriding treatment, nitriding depth 0.5-0.8mm, surface hardness ≥ HV840

|

|

4.8.5

|

Features: There is no need to remove

the mold core rod when replacing the mold core and mold sleeve. After the

low-speed eccentricity adjustment, the concentricity will not change when the

speed is increased to the normal production speed. The eccentricity

requirement is less than 15%. Diameter deviation is within the standard

tolerance range of cable products

|

Ningbo Capstian Technology Co.,Ltd.

Ningbo Capstian Technology Co.,Ltd.