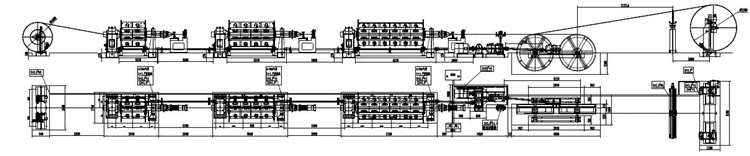

500/1+6+12+18 Rigid Stranding Machine With Ground Shaft Driving.

1.Use:

It is mainly used for sector conductor stranding, circular conductor stranding, drawing and pressing,

as well as the stranding of large square steel core aluminum strand.

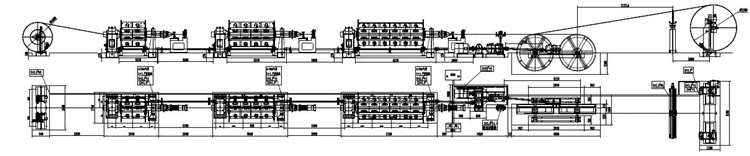

500/1+6+12+18 Rigid Stranding Machine With Ground Shaft Driving.

1.Use:

It is mainly used for sector conductor stranding, circular conductor stranding, drawing and pressing,

as well as the stranding of large square steel core aluminum strand.

|

2.1 |

Strand Single wire diameter |

Copper φ1.5-5.0m |

|

|

Aluminumφ1.8-5.0mm |

|||

|

2.2 |

Max strand O/D |

45mm |

|

|

2.3 |

Strand cage rotation speed |

6 bobbins |

241r/min |

|

12 bobbins |

216r/min |

||

|

18 bobbins |

193r/min |

||

|

2.4 |

Strand pitch |

6 bobbins |

44-850mm |

|

12 bobbins |

52-937mm |

||

|

18 bobbins |

61-1106mm |

||

|

2.5 |

Traction line speed |

60m/min |

|

|

2.6 |

Pay-off bobbin size in frame |

PND 500 |

|

|

2.7 |

Traction wheel size |

φ2000mm |

|

|

2.8 |

Central pay-off size |

PN500-PN630 |

|

|

2.9 |

Take-up bobbin size |

PN1250-PN2500 |

|

|

2.10 |

Main motor power |

75Kw |

|

|

3.1 |

φ500-630 centre Pay-off |

1 set |

|

3.2 |

6. 12.18 bobbins strand cage |

Each 1 set |

|

3.3 |

Rotation compacting unit |

2 set(12 and 18 bobbin cage) |

|

3.4 |

Meter counter |

1 set |

|

3.5 |

φ2000 double traction device |

1 set |

|

3.6 |

φ2000 take-up and traverse device |

1 set |

|

3.7 |

Electric control system |

1 set |

|

3.8 |

Transmission system |

1 set |

|

3.9 |

Safety protection fence |

1 set |

|

3.10 |

Anchor bolt |

1 set |

|

4.2.1 |

Adapt bobbin size |

PND500 |

|

4.2.2 |

Adapt bobbin size |

500x125x375mm |

|

4.2.3 |

Rotation speed change |

6 |

4.2.4 Take-up tension mechanical friction control, manual adjustment

.4.2.5 Electric turbine clamping structure, automatic locking, easy to operate, fast and safe. The turbine is supported by bearings, which is accurate in positioning and is not easy to wear, so as to avoid jamming.

4.2.6 The gearbox is made of hard-toothed gears with positive and negative gears and neutral gear. Each gearbox is equipped with a lubricating oil pump to force lubrication..

4.2.7 Equipped with the most advanced, single-disc, pulse-breaking parking protection device, the system can stop and brake in time when the coil is completed or disconnected..

4.2.8 The frame adopts CNC laser cutting and blanking, overall bending, high temperature annealing treatment after welding forming to eliminate internal stress and increase mechanical performance, and then it is processed by large machine tool as a whole to ensure concentricity, stable operation, high mechanical strength and long-term deformation.

4.2.9 Single-line pre-variable device at the front end of each cage.

4.2.10 Adopt pneumatic brake device to ensure multi-point synchronization and rapid braking.