|

4.2.7

the stranding cage is operated through the touch screen of human-machine

interface, and the start, stop, inching and other operations of the winch

cage are coordinated and controlled by PLC to ensure the synchronization of

each unit in any running state. The man-machine interface can input and

display various data of the winch, such as speed, pitch, production speed,

etc., which is easy to operate.

4.2.8

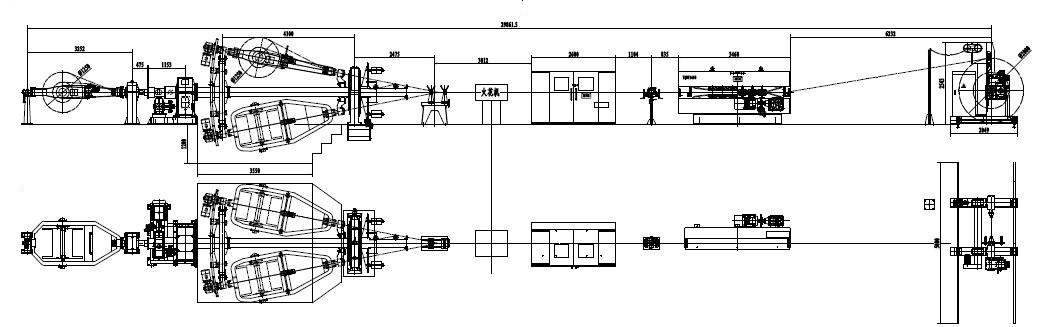

Φ 1250 / 3 bobbin stranding cage is composed of reducer box, large bearing

seat, brake disc, wire disc rack, cradle support disc, etc. The winch cage is

supported by reducer box and large bearing seat, and the cradle is arranged

in three equal parts with conical structure design. The main shaft is a whole

high-quality seamless steel pipe, and the support plate of reel frame is

connected with the main shaft by a combination of flat key and expansion

sleeve. The large pressure plate is welded and annealed. Driven by a single

AC variable frequency motor, it has left and right stranding function. The

planetary gear mechanism is used to realize 100% back twisting.

4.2.9

the whole machine is designed for high-speed operation, without tugboat

bearing, and can be loaded and operated through the internal bearing of

reducer box and large bearing seat. The inner part of the gearbox is

lubricated by the spray of the oil pump motor; The large bearing seat adopts

labyrinth seal structure, which circulates oil supply, lubrication and

cooling through oil pump motor (patented design). Ensure the stability of

high-speed operation.

4.2.10

planetary gear is adopted in the unwinding mechanism of the winch cage, which

can bear large torque and operate stably.

4.2.11

the stranding cage is separately driven by 45KW AC motor with built-in

encoder. The encoder runs in the closed-loop control system and is controlled

by PLC and all units in a unified and coordinated way.

4.2.12

pay off tension: the reel frame provides the required tension for pay off

through mechanical belt friction, and the tension is adjusted manually.

4.2.13

braking system: cage braking: the braking process is coordinated by PLC

through the air brake, frequency converter and braking resistor. The whole

braking process is synchronized with the whole machine to ensure the

stability of pitch.

4.2.14

There are 12 sets of filling rope pay off frames at the outgoing end of 1250

/ 3 stranding cage.

4.2.15

others:

4.2.15.1

the stranding cage is equipped with various protections, such as fault alarm

of driving motor, over temperature alarm of large bearing, insufficient oil

supply alarm of circulating oil, etc. When there is a fault, the man-machine

interface prompts to display the specific fault information, which is convenient

for troubleshooting and maintenance.

4.2.15.2

the back support of the pay off frame of the main winch cage adopts triangle

structure, which is welded by steel plate and tempered. This structure can

reduce the load of the components, not reduce the bearing strength, and avoid

deformation and cracking over time.

4.2.15.3

with the improvement of the overall structure, compared with the tugboat

structure, the corresponding optimization has been made, which makes the

cable travel more smoothly, the wire bending less, and the operation more

convenient.

4.2.15.4

the front support adopts large-scale bearing, which can effectively improve

the running speed, avoid maintenance, reduce the failure rate and increase

the bearing strength compared with the tugboat structure

|

Ningbo Capstian Technology Co.,Ltd.

Ningbo Capstian Technology Co.,Ltd.