XJ-90+70 Rubber cable vulcanization line

1.Application:

The unit is applicable to the production of insulation sheaths of natural, styrene butadiene, green butadiene, CPE, ethylene propylene, chlorinated polyethylene, chlorosulfonated polyethylene, silicone rubber and other rubber cables. Single layer, double layer and double color lines (yellow/green) can be realized.

2.Main technical parameters

2.1

Core

OD before extrusion

Ф

10- Ф 30 (single layer) ,Ф 10mm(double layer)

2.2

Cable

OD after extrusion

Ф

40 (single layer) ,Ф 15mm(double layer)

2.3

Heating

way

Steam

2.4

Coiling

way

Water

2.5

Tube

length

60m

(between upper sealing and lower sealing)

2.6

Tube

specification

DN190

× 6 Length: 60m

2.7

Tube

material

stainless

steel seamless steel tube (304)

2.8

Tube

fabrication

Inclined

2.9

Front

capstan wheel

Φ800mm

Magnetic powder tension

2.10

Main

pneumatic caterpillar

1600kg

2.11

Pay-off

bobbin size

PN630-PN1800

2.12

Take-up

bobbin size

PN630-PN1800

2.13

Line

speed

Not

less than 60m/min

2.14

Power

supply

Neutral

conductor 3-phase 380V/220V ± 10% 50Hz ± 1Hz

2.15

Compressed

air (standard industrial compressed air) pressure

8MPa

3.1

Φ

1800 Column active pay-off rack

2 set

3.2

Φ400/12m horizontal accumulator

1

set

3.3

Φ800 wheel type magnetic powder

tensioning

1

set

3.4

XJ-

Φ 90/16 rubber extruding machine

1 set

3.5

XJ-

Φ70/16 rubber extruding machine(Movable)

1 set

3.6

Hydraulic

upper sealing

1 set

3.7

Vulcanized tube

60m

3.8

Hydraulic

lower sealing

1 set

3.9

Stainless

steel cooling water tank

5m

3.10

Multi

claw blow dryer

1 set

3.11

Ф40mm double layer corsshead

1

set

3.12

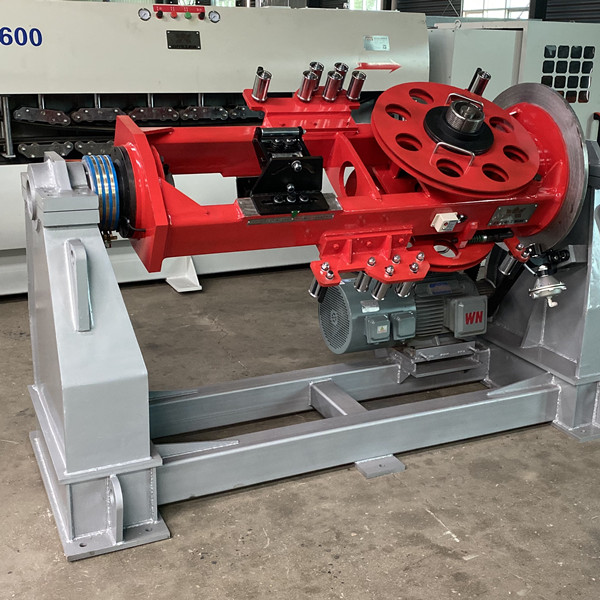

1600kg main caterpillar

1 set

3.13

Φ

1800 Column take-up and traverse line rack

1

set

3.14

Positioning

wheel, steering wheel, limit roller

1

set

3.15

Control system

1set

3.Main

Component

Control system:

Power three-phase five wire system, 380V (± 10%), 50HZ, single-phase control voltage 220V

The operating system of the whole machine is controlled by PLC module, which can be controlled by single action or linkage speed regulation. The operation is visualized through the Hepmont 10.1 inch touch screen

Communication control is adopted between PLC and frequency converter, which has higher control accuracy and faster response than analog variable speed regulation; At the same time, PLC is equipped with Ethernet interface, and users can monitor remotely

The whole machine is a dual control system: the touch screen is used to set the analog speed regulation and the manual self reset knob speed regulation. The parameters can be set and adjusted freely through the touch screen, and can also be controlled by the self reset knob speed regulation

The host machine and traction motor of the extrusion machine are all brand AC motors controlled by frequency conversion speed regulation system. The latest generation of intelligent electronic display calculus temperature controller is selected as the temperature control instrument, with a temperature control accuracy of ± 2 ℃

The panel is equipped with various instruments, indicators, switches and other necessary elements, and various overload, overheating, overcurrent and other protection functions are complete

The low-voltage components of the whole machine are all domestic top brands (Chint or Schneider), which have the advantages of stable starting, running and stopping of the production line, energy conservation and consumption reduction

The control box is spliced by high-quality anodized aluminum profiles and aluminum die-casting corner components, which is simple and stable in appearance and easy to operate. The dust-proof filter device is installed in the main control box to prevent dust from affecting the service life of electrical components in the cabinet.

The safety protection of the production line shall meet the national requirements

Ningbo Capstian Technology Co.,Ltd.

Ningbo Capstian Technology Co.,Ltd.