What is the difference between separate motor drive and ground shaft drive?

The technology of cable machinery is constantly updated. More and more cable factories are willing to use more advanced equipment. On the one hand, the machine is easy to operate, on the other hand, it can greatly save labor costs. A production line needs several people to operate together, but now only one person can complete it. At the same time, the machine operation is more simple, so some more mature factories actively follow up the pace of the times and have fully adopted new technologies. The most important link in the operation of the machine is the transmission mode. In the past, most of them used ground shaft driving, but now more cable equipment manufacturers incline their production center to the separate motor driving. Do you know the difference between ground shaft driving and separate motor driving, and do you have any advantages and disadvantages?

1. What is separate motor driving? Many people also call it independent motor driving. The main meaning is that each part of the machine in the whole production line has a separate motor control and provides power. For example, the common rigid stranding machine has an independent motor drivinh for its winch cage, capstian, take-up and pay off.

2. What is ground shaft driving? It is also called time belt driving. In fact, the whole production line has a motor connected through the ground shaft of all machines through the belt. one main motor driving the ground shaft to rotate through the belt pulley and transmit it to each component, mainly including the main stranding cage and capstan.

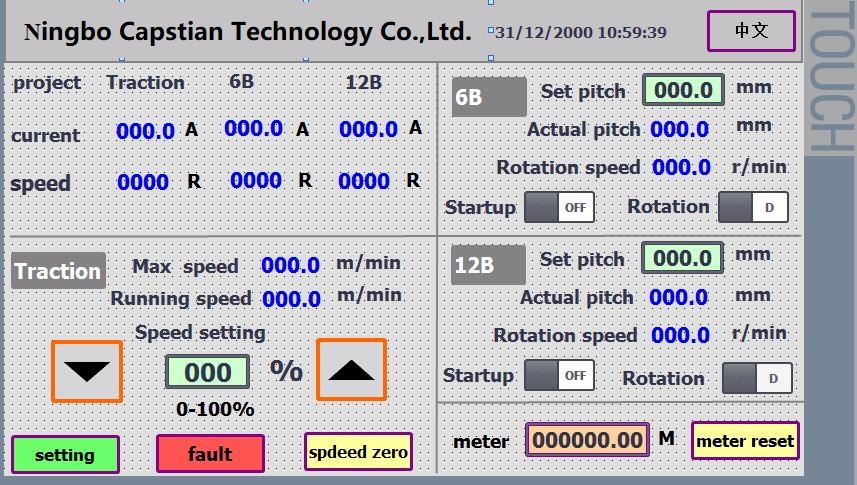

Operation:separate motor driving: all groups are controlled by PLC and IHM. Only one worker needs to stand in the main operation cabinet and set the machine speed, pitch, synchronization, etc. through the touch screen. Although the principle of the ground shaft driving is the same, but the ground shaft drive requires manual adjustment of each component.

Pitch adjustment: the separate motor driving adopts stepless adjustment of pitch. We become stepless adjustable, which means that manual adjustment is not required. When you set a range on the PLC, when you produce different wire, it will automatically adapt to the corresponding pitch. The ground shaft driving needs manual adjustment. Although it also has PLC, the pitch adjustment needs to be based on different wire sepecification. There is a gearbox on the capstan to produce different wire It is very inconvenient to manually adjust the gear on the gearbox.

Synchronization: the synchronization of the separate motor driving needs to be very accurate, so it should be very strict for the producer. If the synchronization is not adjusted well, the user will bring a lot of trouble in later use. The synchronization of ground shaft driving is relatively easy to realize. It is thought that the whole production line is driven by a main shaft, and the speed ratio of all parts is constant.

Here I think of a problem. Some guests need to replace one section of the stranding cage due to the aging of the equipment after using the separate motor drivingmachine for a long time. In order to save costs, they need to buy a section of the stranding from the manufacturer. However, since the machine is separate motor driven, it is very difficult to match. They think that the machines of each manufacturer are different, It is difficult to achieve synchronization and consistency. However, the ground shaft driving is easy, because the replacement can be completed as long as the speed ratio is provided.

If you have any suggestions, please contact Max Xu.

cabletwister@126.com

+8618606615951

Ningbo Capstian Technology Co.,Ltd.

Ningbo Capstian Technology Co.,Ltd.