Coaxial cable can be used for analog signal and digital signal transmission. It is suitable for a variety of applications, among which the most important are television transmission, long-distance telephone transmission, short-distance connection between computer systems and LAN. As a means of transmitting TV signals to thousands of households, coaxial cable has developed rapidly, which is cable TV. A cable TV system can load dozens or even hundreds of TV channels, and its transmission range can reach tens of kilometers. Coaxial cable has long been an important part of long-distance telephone network. Today, it faces increasingly fierce competition from optical fiber, ground microwave and satellite.

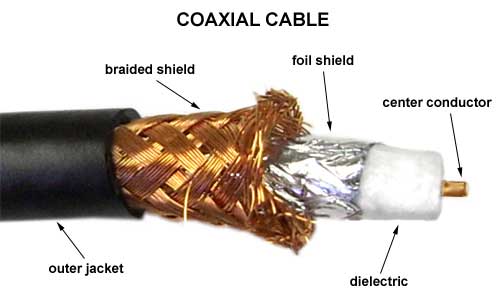

The coaxial cable is divided into four layers from inside to outside: central copper wire (single strand solid wire or multi strand stranded wire), plastic insulator, mesh conductive layer and wire sheath. The central copper wire and the mesh conductive layer form a current loop. It is named because the central copper wire and the mesh conductive layer are coaxial.

Coaxial cables conduct alternating current rather than direct current, which means that the direction of current is reversed several times per second.

If a common wire is used to transmit high-frequency current, this wire will be equivalent to an antenna transmitting radio. This effect consumes the power of the signal and reduces the strength of the received signal.

Coaxial cable is designed to solve this problem. The radio emitted by the central wire is isolated by the mesh conductive layer, which can control the emitted radio by grounding.

There is also a problem with coaxial cable, that is, if a certain section of the cable is greatly squeezed or twisted, the distance between the central wire and the mesh conductive layer is not consistent, which will cause the internal radio waves to be reflected back to the signal transmission source. This effect reduces the acceptable signal power. In order to overcome this problem, a layer of plastic insulator is added between the central wire and the mesh conductive layer to ensure the consistent distance between them. This also causes the cable to be stiff and not easy to bend.

Coaxial cable

In essence, the shielding material of coaxial cable is mainly to improve the outer conductor, which has developed from the initial tubular outer conductor to single-layer braid and double-layer metal. Although the shielding performance of the tubular outer conductor is very good, it is not easy to bend and inconvenient to use. The shielding efficiency of single-layer braiding is the worst. The transfer impedance of double-layer braiding is 3 times lower than that of one-layer braiding. It can be seen that the shielding effect of double-layer braiding is much better than that of single-layer braiding. Each Datong axis cable manufacturer is constantly improving the outer conductor structure of the cable to maintain its performance.

After understanding the structure and distance, in fact, we already know that the main machines for producing coaxial cable are extruder and copper wire braiding machine, among which extruder is the most important. We recommend 50+70 foam extruder.The specific configuration is as follows:

|

No |

component |

spec |

qty |

remark |

|

1. |

Passive pay-off |

Φ500-Ø800 |

1 |

customerize |

|

2. |

Front caterpillar |

800KG |

1 |

Magnetic powder tension |

|

3. |

Wire straightening |

40.0mm |

1 |

Spring tension |

|

4. |

Ø50 foaming extruder |

high pressure |

1 |

Power 15KW |

|

5. |

Ø70 out lyaer extruder |

diameter 35 |

1 |

power 37KW |

|

6. |

Double layer fine tuning head |

30mm |

1 |

6-30mm |

|

7. |

Nitrogen injection system |

high pressure |

1 |

Diamond eye mask |

|

8. |

Dryer+hopper |

100KG |

1 |

Floor type |

|

9. |

PLC control system |

siemens |

1 |

380 voltage |

|

10. |

Stainless steel movable cooling water sink |

2M |

1 |

RKC temperature control |

|

11. |

Static capacitance in water |

adjust |

1 |

beita |

|

12. |

Fixed stainless steel cooling water tank |

18M |

1 |

20-80mm |

|

13. |

Wind blow dryer |

Blower |

1 |

5P |

|

14. |

Caterpillar |

1600KG |

1 |

20-80mm |

|

15. |

Power frequency spark machine |

25KV |

1 |

0-25KV |

|

16. |

Portal type take-up and traverse line stand |

Φ1250-Ø1600 |

1 |

laod 5 ton |

Ningbo Capstian Technology Co.,Ltd.

Ningbo Capstian Technology Co.,Ltd.