What is the key when you buy cable equipment?

With the rapid development of information technology in various countries and increasing investment in infrastructure, cable, as an important part of people's livelihood project, is like the blood connecting the world network, which is related to thousands of people. As a cable producer, seeing the opportunity of development, they have enthusiastically invested in it, and investors all over the world scramble to buy cable equipment.

Due to the limitation of funds, compared with the equipment of a few well-known manufacturers in the world, because it is very expensive, many buyers stop and focus on more practical and low-cost cable manufacturers.

As experts in the cable industry, we have analyzed the problems encountered by many customers when buying and using machines, and found a very characteristic feature: buyers often pay special attention to the cost of machines and ignore the waste of raw materials in production.

After specific analysis, the results are very terrible. The loss of neglected links is often greater than the cost of investment. Let's make a specific analysis below:

We use the same machine to produce the same type of cable and compare different machine configurations

The two machines mainly produce bare copper, bare aluminum wire and copper wire shielding. The single wire diameter of the conductor ranges from 1.0 to 5.0mm, and the maximum cross-sectional diameter after stranding is 45mm.

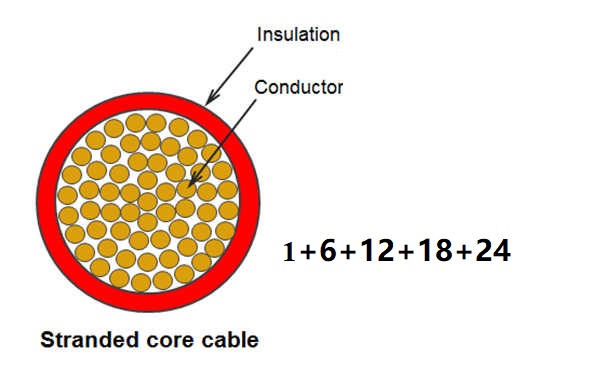

1. Firstly, connect the customer's demand for purchasing the machine in order to produce a cross-section upto 300mm2 stranded wire. And the structure of the line is shown in the figure:

2. For the same production line, both machines can be met, but the cost is very different. For example, the price of 500 / 24 bobbin rigid stranding machine is about 65000-75000usd. While the price of 500 / 1 + 6 + 12 + 18 + 24 bobbin rigid stranding machine is about 110000-130000 USD. The difference is doubled. Therefore, in order to save cost, the customer chose a cheaper 500 / 24 model. This can save about 75000usd. You can use this money to buy other equipment.

However, its disadvantage is that the structure of the line produced by the 500 / 24 machine is relatively loose, which is not as regular as 500 / 1 + 6 + 12 + 18 + 24. At the same time, due to frequent startup and line change, it is also a certain loss to the machine.

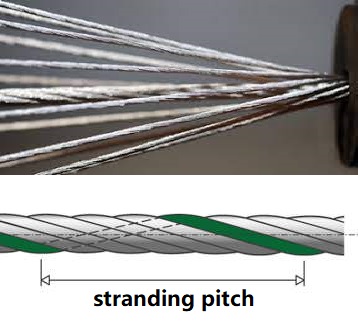

3. After customers purchase machines and put them into production, generally new investors do not care about the waste of raw materials due to their rich profits, but experienced producers will find a slight difference: the key lies in the stranding pitch.

Calculation method: for example, the pitch range of frame winch is 48-860mm. If the maximum pitch is 860mm, we waste 0.001g. 200R / min per minute for each pitch produced 860mm, work 8 hours a day, 20 days a month and 240 days a year. 1g x 200R / min x 60 minutes x 8 hours x 20 days x 12 months = 23040000g, about 23 tons. At present, the price per ton of copper rod is 9812usd / ton. The total price of one year is 23x9812 = 225676usd. Although the accuracy of the figure is not completely correct, it also reflects some problems. That is, customers must understand their own production situation and find the most reasonable scheme when purchasing cost.

Finally, all the above analysis is my personal opinion, but it also gives customers a good suggestion. Every factory needs a very experienced and professional chief technical engineer, whose role is far beyond your imagination.

Max Xu- Wire machine expert in China.

Ningbo Capstian Technology Co.,Ltd.

Ningbo Capstian Technology Co.,Ltd.