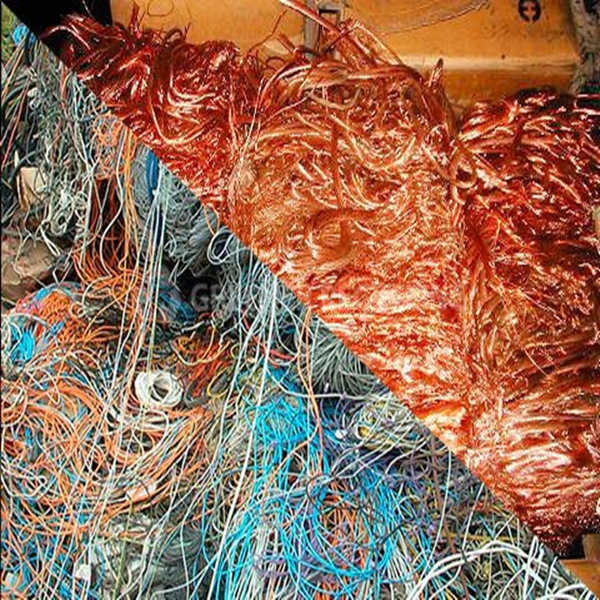

Many wires or cables have become a major part of the industry today. Various stranding and cabling machines are used to produce various cables, including optical cables.

The following are just a few of them:

Rigid frame stranding machine:

The rigid frame strander is a cage strander without reverse twisting. Multipurpose rigid cage winch for

Twist aluminum wire and copper wire into round, compressed and compact bare wire;

Production of overhead power transmission cables, such as steel cored aluminum strand;

Multi strand Milliken conductor (sectional conductor);

Shielded power cable with copper wire;

Stranded insulated conductor.

A typical production line includes the ability to string 37 or 61 elements in one pass, with a series option to further enhance the capacity of the production line. The cage has various structural types, with various reel braking systems (reel brake with DC motor, electromagnetic brake, pneumatic brake and mechanical brake) and loading systems (overhead loading and side loading)

Drum twister:

The drum twister can be used for round, compressed, compact and fan-shaped insulated core wires, stranded Milliken conductors, steel wire armor and shielding on power cables, etc. The copper core of the typical machine for producing Milliken cable is made of sections separated by paper tape, as follows: 1 portal traverse pay off frame, 5 rotary pay off frames, 4 fpr 80bobbins packing frames, 3 segmented belt conveyors, 1 central packing pay off frame, 1 rotary crawler, 1 rotary coiler, control system (PLC + computer), etc.

Milliken Conductor:

For alternating current, the current outside the conductor is more than that in the center (skin effect). In order to overcome this problem, larger conductors usually adopt Milliken structure. This conductor consists of several separate sectors, usually four for distribution cables and six for hollow liquid filled cables. Apply a thin layer of paper or other suitable insulating material to the alternating sectors. Use this structure to purge 900mm ² There is not enough economic advantage, but Milken design can also be used to obtain greater conductor flexibility.

In the United States, this kind of conductor is usually called segmented structure.

Laying and wrapping such a bare copper department requires a complex machine (tension control) and real expertise.

Ningbo Capstian Technology Co.,Ltd.

Ningbo Capstian Technology Co.,Ltd.