What machine is most suitable for producing ACSR?

First, we need to understand what is ACSR?

Aluminum conductor steel reinforced (ACSR), English Name: aluminum conductor steel reinforced, refers to the reinforced conductor with single-layer or multi-layer aluminum strand stranded outside the galvanized steel core wire. It is mainly used in power and transmission line industries.

Related structures:

Steel cored aluminum strand is made of aluminum wire and steel wire, which is suitable for overhead transmission lines.

It has a steel "core" inside and an aluminum wire wound around the steel core by stranding; The steel core is mainly used to increase the strength, and the aluminum strand is mainly used to transmit electric energy;

Main application:

For high-voltage transmission lines, because the path of the line is limited and it is impossible to build multiple lines on one path, people have come up with the method of using one path, a set of iron towers and hanging multiple conductors, that is, one line is equivalent to building multiple lines; For 500kV transmission lines, China mostly adopts the method of hanging four conductors. This method of stringing is called parallel erection of the same tower.

Related advantages:

Steel cored aluminum strand has the characteristics of simple structure, convenient erection and maintenance, low line cost, large transmission capacity, convenient laying across rivers and valleys and other special geographical conditions, good electrical conductivity, sufficient mechanical strength, large tensile strength, enlarged tower distance, etc. Therefore, it is widely used in overhead transmission and distribution lines of various voltage levels.

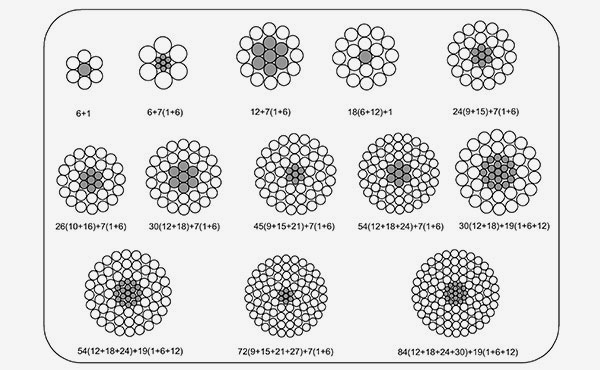

We can see from the picture that the most critical part of ACSR is the steel strand in the center, and its material determines the structure and model of the machine. For example, most factories use high-carbon steel wire, and the consumption is very large, so general guests hesitate between tubular strander and skip strander when choosing the machine. Let's analyze their respective advantages and disadvantages.

1, skip strander: eg. 7 core ACSR. it use 630/1+6 structure. Bow stranding machine is mainly used in the compacted strand of bare aluminum wire, bare copper wire and steel cored aluminum strand, and the product also has many advantages in the process of use. When in use, the central shaft will not be loaded by the weight of the reel, and the resistance strength of the product is very high. In the process of operation, the speed is very high and has a very good rotational inertia. The overall performance is very outstanding and superior. Moreover, it adopts the tradition of 36 level variable pressure box, and the writing has a very good effect, At the same time, the risk is a natural separation, which can effectively prevent any phenomenon in the gluing process of the product. This product adopts a very advanced short-term parking device, which can directly control each reel. If the reel is broken, it will stop automatically. Therefore, it has a very outstanding performance in the process of use, and can give better play to its efficacy and performance.

2.tubular strander: it can use 630/1+6 structure, if you want to reduce cost, 500/1+6 is suitable too.It is made of the structure of the rotating body supporting the main body of the large bearing. The product can improve the operation speed of the equipment in the process of use. It is very strict in the process of operation. In addition to the very stable effect, it also has a very good bearing capacity, so as to prolong its service life, The product adopts the three window structure, the overall welding and stress process are very good, and it also has a very stable effect in the process of use. At the same time, after welding, it can improve the assembly and installation accuracy of the unit, play the supporting role of bearing assistance, and the installation accuracy and operation are also very good, While reducing the noise, the running speed is also very high. At the same time, there are new equipment and fixed pay off rack, and the selection of this product is a traditional system. At the same time, its protection system and electric control cabinet play a very key role.

Special attention: Although the speed of skip strander can reach 500-700r / min and that of 630 tubular strander can only reach 350r / min, the structural strength is better than skip strander, and due to its stable operation, the quality of the stranded wire is better.At the same time, the strength of steel wire also determines the defect of skip strander。

Ningbo Capstian Technology Co.,Ltd.

Ningbo Capstian Technology Co.,Ltd.