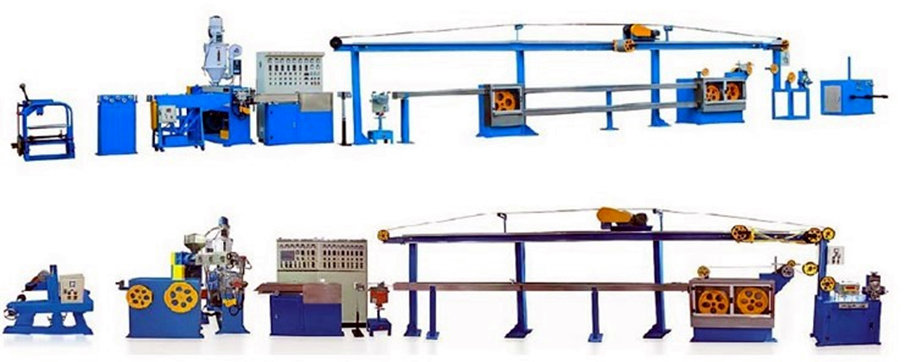

The working principle of the extruder is to use the screw of specific shape to rotate in the heated barrel to squeeze the plastic sent from the hopper forward to make the plastic plasticize evenly (i.e. melt). Through the machine head and molds of different shapes, the plastic is extruded into plastic layers of various shapes required for continuity, and extruded on the wire core and cable. Plastic extrusion process

The plastic insulation and sheath of wires and cables are made by continuous extrusion. The extrusion equipment is generally a single screw extruder. Before extruding the plastic, check whether the plastic is wet or there are other sundries, and then preheat the screw and add it into the hopper. In the extrusion process, the plastic loaded into the hopper enters the barrel with the help of gravity or feeding screw, advances continuously under the thrust of the rotating screw, and moves gradually from the preheating section to the homogenization section; At the same time, the plastic is stirred and extruded by the screw, and changes into a viscous flow state under the action of the external heat of the barrel and the shear friction between the plastic and the equipment, forming a continuous and uniform material flow in the screw groove. Under the action of the temperature specified in the process, the plastic changes from the solid state to the molten state, and then the fully plasticized plastic is pushed into the machine head through the push or stirring of the screw; The material flow reaching the machine head is extruded from the die sleeve mouth through the annular gap between the die core and the die sleeve, extruded and wrapped around the conductor or wire core to form a continuous and dense insulating layer or sheath layer, and then cooled and solidified to make wire and cable products. Three stages of extrusion process

The main basis of plastic extrusion is the plasticity of plastics. Plastic molding in extruder is a complex physical process, which includes mixing, crushing, melting, plasticizing, exhaust, compaction and final molding. It is worth noting that this process is implemented continuously. However, it is customary for people to artificially divide the continuous process of extrusion process into different stages according to different reactions of plastics, namely: plasticization stage (mixing, melting and homogenization of plastics); Forming stage (extrusion of plastics); Setting stage (cooling and curing of plastic layer).

The first stage is plasticization. Also known as the compression phase. It is completed in the barrel of wire and cable extruder. Through the rotation of screw, the plastic changes from granular solid to plastic viscous fluid. There are two sources of heat obtained by plastics in the plasticization stage: one is the electric heating outside the barrel; The second is the friction heat generated when the screw rotates. The initial heat is generated by the electric heating outside the barrel. After normal start-up, the heat is generated by the friction between the material and the inner wall of the barrel and the internal friction between material molecules during compression, shear and mixing.

The second stage is the molding stage. It is carried out in the machine head. Due to the rotation and pressure of the screw, the viscous fluid is pushed to the machine head. Through the mold in the machine head, the viscous fluid is formed into extruded materials of various sizes and shapes, and coated outside the core or conductor.

The third stage is the finalization stage. It is carried out in the cooling water tank or cooling pipe. After cooling, the plastic extruded layer changes from amorphous plastic state to finalized solid state.

Changes of plastic flow during plasticization

In the plasticizing stage, the plastic is pushed to the head by the screw along the axial direction of the screw. In the process of movement, it experiences changes in temperature, pressure, viscosity and even chemical structure. These changes are different in different sections of the screw. The plasticizing stage is artificially divided into three stages according to the physical state change process of plastic flow, namely feeding section, melting section and homogenization section. This is also the segmentation method of extrusion screw. Each section has different effects on plastic extrusion, and the plastic presents different forms in each section, thus showing the extrusion characteristics of plastic.

In the feeding section, firstly, the softening temperature is provided for the granular solid plastic, and secondly, the shear stress generated between the rotation of the screw and the fixed barrel acts on the plastic particles to realize the crushing of the softened plastic. The most important thing is to generate enough continuous and stable thrust and reverse friction by screw rotation to form continuous and stable extrusion pressure, so as to realize the mixing and uniform mixing of broken plastics, and preliminarily implement heat exchange, so as to provide the basis for continuous and stable extrusion. Whether the thrust generated at this stage is continuous, uniform and stable, whether the shear strain rate is high or low, and whether the crushing and stirring are uniform directly affect the extrusion quality and yield.

In the melting section, the old plastic after crushing, softening and preliminary mixing moves along the screw groove to the machine head due to the pushing action of the screw, and enters the melting section from the feeding section. In this section, the plastic encounters the heat effect of higher temperature, which is the heat source of the. In addition to the point heating outside the barrel, the friction heat of screw rotation also plays a role. The thrust from the feeding section and the reaction force from the homogenization section make the plastic form a backflow during the advance. The backflow is generated in the screw groove and the gap between the screw and the barrel. The backflow not only further evenly mixes the materials, but also increases the heat exchange effect of wire and cable plastic, so as to achieve the heat balance of the surface. Because the action temperature at this stage has exceeded the rheological temperature of the plastic, and the action time is long, the physical state of the plastic has changed, and the materials in contact with the heating barrel begin to melt, forming a layer of polymer molten film on the inner surface of the barrel. When the thickness of the molten film exceeds the gap between the screw top and the barrel, it will be scraped off by the rotating thread, Gather in front of the propulsion thread to form a molten pool. Due to the relative movement between the barrel and the root of the thread, the circulating flow of materials occurs in the molten pool. Behind the screw edge is the solid bed (solid plastic). In the process of moving forward along the screw groove, as the screw groove depth of the melting section gradually becomes shallower to the homogenization section, the solid bed is continuously squeezed to the inner wall of the barrel, accelerating the heat transfer process from the barrel to the solid bed. At the same time, the rotation of the screw has a shear effect on the molten film on the inner wall of the barrel, so as to melt the material at the interface between the molten film and the solid bed, The width of the solid bed decreases gradually until it disappears completely, that is, it changes from solid state to viscous flow state. At this time, the molecular structure of plastics has fundamentally changed, and the intermolecular tension is extremely relaxed. If it is a crystalline polymer, its crystal region begins to decrease and amorphous increases. In addition to the extra large molecules, the main body has completed plasticization, that is, the so-called "preliminary plasticization", and under the action of pressure, the gas contained in the solid material is eliminated to realize preliminary compaction.

In the homogenization section, there are several outstanding process characteristics: the screw thread depth in this section is the shallowest, that is, the screw groove volume is the smallest, so this is the working section with the largest pressure between the wire and cable screw and the barrel; In addition, the thrust from the screw and the reaction force at the sieve plate are the direct zone of "close combat" of plastics; This section is the section with the highest extrusion process temperature, so the plastic is subjected to the maximum radial pressure and axial pressure at this stage. This high pressure is enough to remove all the gas contained in the plastic and compact the melt. This section is called "pressure equalizing section". Due to the effect of high temperature, the polymer that has not been plasticized through the melting section completes plasticization in this section, so as to finally eliminate the "particles" and make the plastic plasticization fully and evenly, and then the fully plasticized and melted plastic is evenly extruded by the machine head quantitatively and at constant pressure.

Flow state of plastics during extrusion

In the extrusion process, due to the rotation of the screw, the plastic moves, while the barrel does not move, which produces a relative motion between the barrel and the screw. This relative motion has a friction effect on the plastic and makes the plastic drag forward. In addition, due to the resistance of the die, porous screen plate and filter screen in the head, the reaction force of the plastic in the forward movement is generated, which complicates the flow of the plastic in the screw and barrel. Generally, the flow state of plastics is regarded as composed of the following four flow forms:

Positive flow refers to the flow of plastic along the screw groove to the machine head. It is produced by the pushing force of screw rotation and is the most important of the four flow forms. The positive flow rate directly determines the extrusion amount.

Backflow - also known as countercurrent, its direction is opposite to that of normal flow. It is caused by the pressure (the forward reaction force of the plastic) generated in the head area because the mold, sieve plate and filter screen in the head hinder the positive movement of the plastic. "Backflow under pressure" is formed from the head to the feeding port, also known as "backpressure flow". It can cause a loss of production capacity.

Cross flow - it is the plastic flow along the axis, that is, the direction perpendicular to the threaded groove. It is also formed by pushing when the wire and cable screw rotates. Its flow is subject to the resistance of the side wall of the thread groove. Due to the mutual resistance of the threads on both sides, and the screw is rotating, the plastic overturns in the thread groove to form a circular flow, so the cross flow is essentially a circular flow. The effect of circulation on the mixing and plasticization of plastics in the barrel into a molten state is inseparable from the action of circulation. Circulation makes the material stir and mix in the barrel, and is conducive to the heat exchange between the barrel and the material. It is of great significance to improve the extrusion quality, but it has little effect on the extrusion flow rate.

Leakage - it is also caused by the resistance of the die, sieve plate and filter screen in the head. However, it is not the flow in the screw groove, but the reverse flow formed in the gap between the screw and the barrel. It can also cause a loss of production capacity. Because the clearance between the screw and the barrel is usually very small, under normal circumstances, the leakage flow is much smaller than the forward flow and reverse flow. In the extrusion process, the leakage flow will affect the extrusion amount, and the extrusion amount will decrease with the increase of leakage flow.

The four flow states of plastics will not appear in a separate form. For a certain plastic particle, there will be neither real backflow nor closed circulation. The actual flow of melt plastic in the threaded groove is the synthesis of the above four flow states, which moves forward in a spiral path.

Extrusion quality

The extrusion quality of wire and cable mainly refers to whether the plasticization of plastic is good and whether the geometric dimension is uniform, that is, whether the radial thickness is consistent and whether the axial outer diameter is uniform. In addition to the plastic itself, the main factors determining the plasticization are temperature, shear strain rate and action time. Too high extrusion temperature not only causes the fluctuation of extrusion pressure, but also leads to the decomposition of plastics, and may even lead to equipment accidents. Reducing the depth of the screw groove and increasing the length diameter ratio of the screw will not only be conducive to the heat exchange of the plastic, prolong the heating time and meet the requirements of plasticization uniformity, but also affect the extrusion volume and make it difficult for the manufacturing and assembly of the screw. Therefore, the important factor to ensure plasticization should be to improve the shear strain rate of plastic caused by screw rotation, so as to achieve uniform mechanical mixing and balanced extrusion heat exchange, so as to provide guarantee for uniform plasticization. The magnitude of this strain rate is determined by the shear strain force between the screw and the barrel. Under the requirement of ensuring the extrusion capacity, the screw groove depth can be increased with increasing the rotating speed. In addition, the gap between screw and barrel also affects the extrusion quality. If the gap is too large, the backflow and leakage of plastic will increase, which will not only cause the fluctuation of extrusion pressure and affect the extrusion quantity; Moreover, due to the increase of these backflows, the plastic is overheated, resulting in plastic scorching or forming difficulties.

Ningbo Capstian Technology Co.,Ltd.

cabletwister@126.com

Ningbo Capstian Technology Co.,Ltd.

Ningbo Capstian Technology Co.,Ltd.