High Frequency Cable Manufacturing Process(USD3.0/1 HDMI)

What is the high frequency cable?

High frequency wire (high frequency signal wire) is a connecting line for high frequency signal transmission. High frequency wire are generally shielded lines, which are lost due to the impedance of the conductor during signal transmission. It is widely used. The common cable TV line is a kind of high frequency wire.

Production process:

1.conductor bunching ----- 2.core wire extrusion----- 3.cored wire pair twisting------- 4.overall stranding ------5. braiding------6. sheathing.

1.Copper wire bunching: apply to HDMI copper wire bunching.

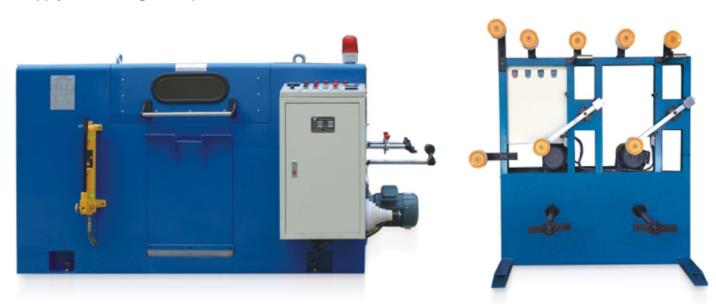

300-500 stranding machine:

2. Core wire extruding: Apply single layer insulation, double layer insulation or single layer insulation+ color injection.

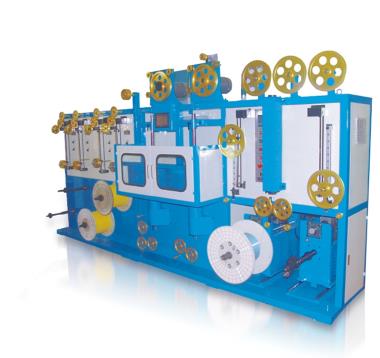

(1). 50+35 chemical foaming insulation extrusion production line.

(2). 40+30+30 Triple layer co-extrusion production line: Apply to jacket-foaming-jacket structure data communication cable, railway signal transmission data cable, high quality small coaxial, micro coaxial cable, HDMI cable triple layer extrusion.

3. Cored wire pair twisting: Apply for CAT5,CAT5E core wire pair twist.

(1).500 pair twisting machine + double initiative pay-off.

(2). 500-630 high speed cantilever single twisting machine: Apply to HDMI,DP,USB etc. high frequency cable, data cable, electronic cable, core wire pair twisting or multi-stands stranding.

(3). Double layer or single layer taping machine; Apply to high frequency data cable single or double layers wrapping.

Machine.

4. 800-1250mm Cantilever single twsting machine: Apply the insulation wire to cabling.

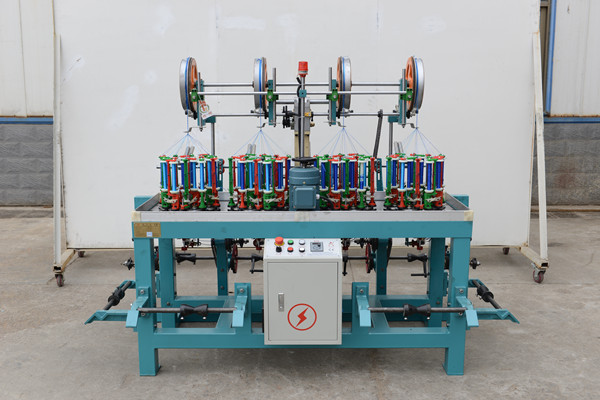

5. High speed braiding machine: Apply to computers, mobile phones, televisions, tale recorders, audio systems, electronics, such as shielding circuit.

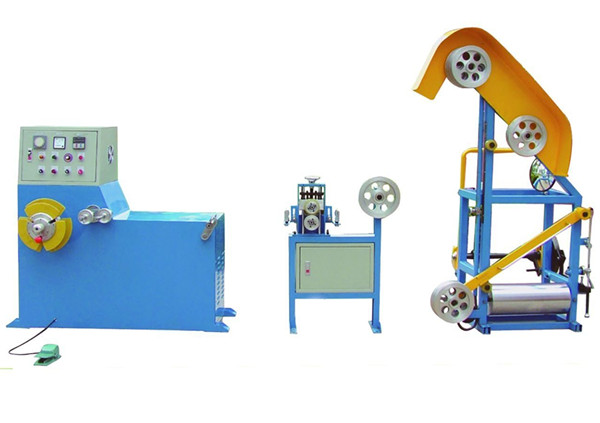

6. SJ-70 Cable extrusion line machine: Apply to sheathing wire and cable by hot extrusion of thermoplastic cable materials such as polyvinyl chloride(PVC), low-smoke and halogen-free.

7.Automatic coiling and packing Machine: Apply to0.5 to 240mm square electric wire and small sectional cable the circle and hit pitchine, this production is high in efficiency, arrange line auality is in the advanced level of the domestic and international like product.

In conclusion, the customer selects the appropriate machine according to the cable specification. In particular, customers need to pay attention to the requirements of production process.

Max Xu - China Wire Machine Expert.

cabletwister@126.com

WhatsApp+8618606615951

Ningbo Capstian Technology Co.,Ltd.

Ningbo Capstian Technology Co.,Ltd.