450/13DL Aluminium Alloy RBD Machine / Copper RBD Machine / Large Copper Rod Breakdown Machine

/ Alumunium Rod Breakdown Machine

Application:

450/13DL Aluminium

alloy rod breakdown machine is used to draw single aluminium alloy wire

from 9.5mm

to 1.8mm-4.5mm.The capstans are arranged in a line that are able to work

continuously

with drawing speed. Electrical control can be matched with each

other.

Compositions of equipment

|

Name

|

Quantity

|

|

1.Cantilever Pay-off

shelf

|

1 set

|

|

2. 450/13DL Main

drawing machine

|

1 set

|

|

3. 300 Tension

controller

|

1 set

|

|

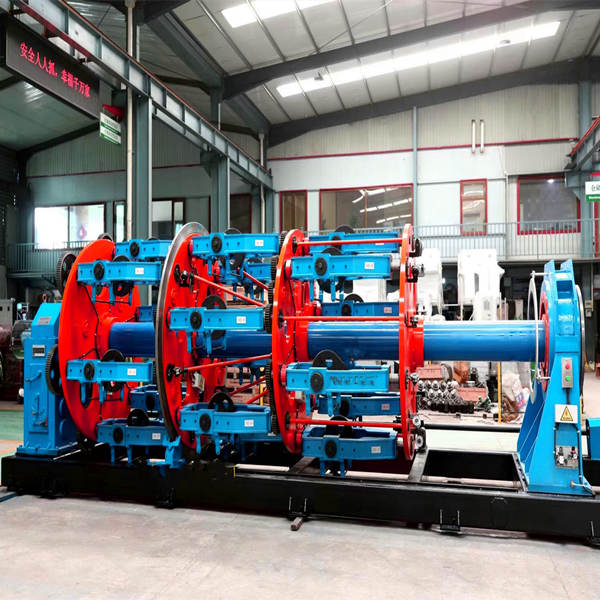

4. SX630 Double

spoolers

|

1 set

|

|

5.Electrical

cabinet

|

1 set

|

|

6.Operation panel

|

1 set

|

|

7.Gear Oil system

(Pump+Cooler)

|

1 set

|

|

8. Wire pointing

& threading machine (9.5mm-1.8mm)

|

1 set

|

|

9. Butt welding

machine (9.5mm)

|

1 set

|

|

10.Spare parts

|

1 set

|

II.Cantilever Pay-off shelf

1.Guide roller type

which is attached ground root.

2.This unit is

composed of a stand and a guide roller.

3.It is adopted

advanced structure which has a single pole with a rotation arm.

4.This pay-off

stand can load 2 rod coils at the same time to pay off wires continuously.

5.Height of pay-off

shelf 5000mm

6.The maximum

diameter of inlet coil 2000mm

7.Guide wheel

diameter 590mm

8.Quantity of

guider 3 pieces

9.Straightening

function for the inlet rod is available

10.Wire tangled

alarming and stop line device

11.With ladder to

climb up

III. 450/13DL Main drawing machine

1.Gearbox is casted

by HT200 accurately as a whole piece. It has many excellent features, for

instance higher rigidity, well sealing performance. Also it will not leak water

and oil and can reduce vibration efficiently. The gearbox is treated with

one-off orientational processing to make sure processing accuracy.

2.In the gear box,

material of bevel gears is 20CrMnTi and it is treated with cemented quenching.

3.The surface of

drawing capstan is in a double-cone shape to enhance its using life greatly.

4.The drawing box

has double covers to seal. Covers are made of stainless steel. The inner cover

has six parts and outer cover has four parts and can be open and closed by

hand.

5.Machine has Five

Foot switch plates.

6.The bearings are HRB,

China best brand.

7.With Two motors,

the machine has Quick Die Change system, save time for wire pointing and

threading, also require less dies.

8.Final rotation

die function is provided.

9.Fix speed capstan

also has outside box and roll up door

10.Lubrication

method Half immerse and Pipe spray

11.Copper rod inlet

position has sensor to detect.

12.Gear

transmission Helical gears

13.Main machine

power transmission is connected directly to machine with Coupling

14.Fix speed motor

power transmission is by Timing belt

15.With sensor to

auto observe final drawing speed

16.With Rotary

Encoder to observe speed(Auto observe one axis speed and auto calculate others)

|

1.Inlet

|

9.5mm (Inlet wire

straightening function is provided)

|

|

2.Outlet

|

1.8mm-4.5mm(Final

wire cleaning function is provided)

|

|

3.Diameter of

capstans

|

450mm

|

|

4.Speed

|

1500m/min,

capacity say 2.5mm, 1180kg per hour

|

|

5.Slip ratio

|

1.38-1.2 decrease

|

|

6.Quantity of

capstan

|

13

|

|

7.Capstan

|

Tungsten carbide

(With wire threading function)

|

|

8.Quick dies change

|

Available /

Require less dies

|

|

9.Main motor

|

DC315KW, with DC

Controller

|

|

10.Fix speed

motor

|

DC75KW, with DC

Controller

|

|

11.Gear

|

Changeable

|

|

12.Noises of

machine

|

≤85 db

|

|

13.Protection

cover

|

Motor

transmission cover installed

|

|

14.Others

|

Cooler for Gear

oil is provided

|

|

15.Others

|

All main pipes

are provided

|

|

16.Others Gear oil recycling complete system is

provided, including: Pump, Gear oil tank, Pipes, Oil Pressure Gauge, Signal

wire. When lack of oil, machine will auto stop.

|

|

17.Others Cooler for Lubrication oil , no need. You

need prepare one Underground Tank for Lubrication Oil recycle.

|

IV.Operation panel (English language)

1.PLC+Touching

screen, Inovance

2.Buttons control

(As back up)

3.With Alarm Light,

Alarm Sound

4.All signal wires

are provided and connected at one end, easy to connect with others

V.Electrical system

1.With Power Meter

to auto record Power consumption.

2.All electric

parts are top brands, easy to replace.

3.All signal wires

are provided and connected at one end, easy to connect with others.

4.With LED lights

and Switches, when open doors, will auto turn on.

VI. 300 Tension Controller

|

1.Purpose

|

When start, stop,

bobbin changing, use it as compensation of line speed micro changing

|

|

2.Type

|

Tensile strength

is adjusted by pneumatic

|

|

3.Air pressure

|

Adjustable within

0.3~0.6Mpa

|

|

4.Accumulating

length

|

ITO standard:

over 7 M

|

|

5.Guide roller

material

|

AL and ceramic

coating treatment

|

|

6.Auto adjust

|

By compressed

air, auto tracking and adjusting wire tension

|

VII. SX630 Double spoolers

1.Applicable wire

range 1.8mm-4.5mm

2.Motor

AC30kw*2set, WanNan motor, with Inovance Inverter

3.Power transmission by triangle belt

Ningbo Capstian Technology Co.,Ltd.

Ningbo Capstian Technology Co.,Ltd.