|

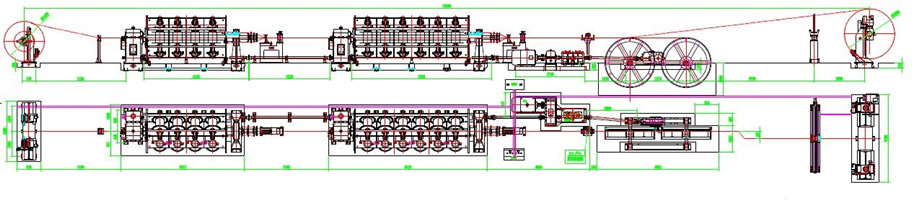

4.1.5. Structural form: the main

engine adopts 12 + 18 two-stage cage layout, and each section of cage is

divided into four equal parts. The cage is carried by two large double row

roller bearings, which are supported by gearbox and front support. The cage

body is composed of cage, gearbox, front support, brake system, base, etc.

The whole machine is driven by 75kW variable frequency motor.

4.1.6. Synchronous stranding: the

12 and 18 reel stranders have the function of synchronous stranding up to 30

cores. The same speed box is used for the two sections of stranding cage, and

12 synchronous pipes are preset inside the 18 reel stranding cage to complete

the stranding of up to 30 wires in the outer layer.

4.1.7. Hanging way: the process of

tightening and loosening the coil is completed by the worm gear clamping

structure driven by the electric wrench, and the turbine box has the function

of automatic locking, which is convenient, fast and safe to operate; The

turbine is supported by bearing, which is accurate in positioning, not easy

to wear and avoid jamming. The coil is installed into the winch cage through

the lifting device in the workshop.

4.1.8 Structural features of

gearbox and front support: the internal gear of gearbox is made of 20CrMnTi

material, carburized, and the grinding accuracy is grade 6. The 6-stage speed

change of the box has positive, negative and neutral gears, and the inside of

the box is sprayed and lubricated by an independent oil pump motor. The front

support is made of gray cast iron with lost foam casting process, which is cast

and processed as a whole, with beautiful appearance and high strength.

4.1.9. Structural characteristics

of the hinge: the frame adopts the plate CNC laser cutting and blanking, and

the large bending machine bending processing. This process can minimize the

welding seam and improve the overall structural strength. After the overall

assembly and welding forming, the high temperature annealing treatment can

eliminate the internal stress, and then the large machine tool is processed

as a whole to ensure the concentricity, stable operation, high mechanical

strength and no deformation for a long time.

4.1.10. Bottom structure: the base

is made of high-quality plate and rectangular square tube, with beautiful

appearance and high structural strength.

4.1.11. Braking system: each

section of the main engine is equipped with multiple groups of flat air

brakes. When parking, the driving motor stops working, and all brakes act at

the same time. The whole braking process is efficient and stable.

4.1.12. Line breaking and parking:

equipped with advanced dxj full-automatic vector pulse line breaking and

parking protection system, the line breaking monitoring can be accurate to

each coil, and the system can stop and brake in time when the wires in the

coil are used or broken. The monitoring system is controlled by wireless

communication to reduce wire laying, improve monitoring accuracy, reduce

operator allocation and improve production efficiency.

4.1.13. Pay off tension: mechanical

friction is used to provide tension, and the tension is adjusted manually.

The tension output is even.

4.1.14. Pre deformer: a single wire

pre deforming device is installed at the front end of each section of main

machine to prefabricate the stranding pitch and improve the quality of

finished wire.

4.1.15. The front end of each

section of the winch cage is equipped with: emergency stop, inching button,

and a 220 V power supply fast plug row, which is convenient for operation and

use.

4.1.16. Wear resistant alloy

nozzles or wire rollers are set at all wire holes and easy to scratch wire

positions.

4.1.17 Safety cover: one side wall

safety net made of perforated plate.

4.118. Others: a group of 30 reels

is added to the 18 reel winch cage, which can be interchanged with the

original 18 reel reels for synchronous stranding

|

Ningbo Capstian Technology Co.,Ltd.

Ningbo Capstian Technology Co.,Ltd.