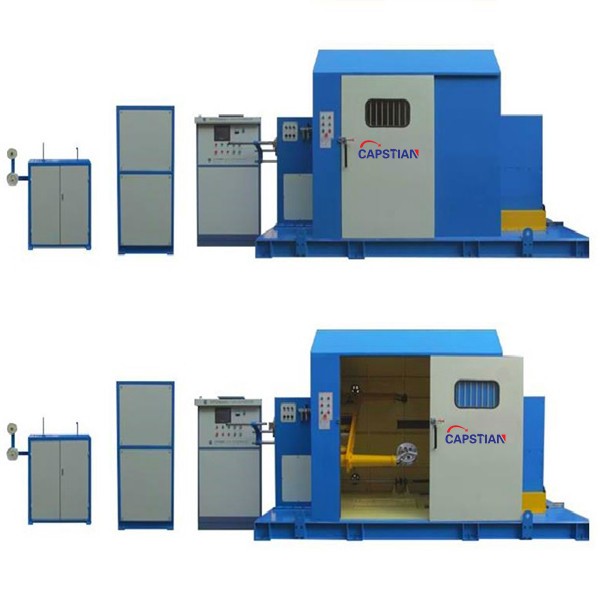

1000mm Cantilever Single Twist Machine / Cantilever Type Single Twist Laying Up Machine /

High Speed Single Twist Cantilever Buncher / Cantilever Type Single Twist Cabling Machine

1. Application:

Suitable for all kinds of wire and cable core stranding (within the allowable range); synchronous completion of concentric wrapping or towing functions.

2. Main Component:

|

2.1 |

Φ630mm electromagnetism pay-off rack 6 head) |

2 set |

|

2.3 |

Assembling die holder |

1 set |

|

2.4 |

Touch screen and PLC control operating cabinent |

1 set |

|

2.5 |

Φ1000 full automatic cantilever single twist machine |

1 set |

3, Equipment configuration

3.1 630mm pay-off rack:

3.1.1 Bobbin size: PND630

3.1.2 Pay-off head quantities: 6 head x 2 set

3.1.3Tension Form: electromagnetism type.

3.2 1000 full automatic cantilever single twist machine

3.2.1. Purpose: (1) PVC, PE, PDF, PDFA, SVJ and other coated core stranded synchronous tape;

(2) All kinds of pure copper, copper-clad steel, copper-clad aluminum and other multi strand conductor bundle wire collection;

3.2.2. Applicable single wire diameter: Φ 0.7 ~ 6.0mm coated wire; Φ 0.05 ~ 2.5mm conductor

3.2.3. Wire diameter after stranding: Φ 20mm max;

3.2.4. Stranding distance range: 30 ~ 400mm < man machine interface arbitrary setting type >;

3.2.5. Rotating speed of swivel arm: 600rpm / max, constant speed: 500rpm;

3.2.6. Range of row spacing: 2 ~ 22mm < arbitrary setting of man-machine interface >;

3.2.7. Coiling reel: the iron shaft and plastic shaft are common, and the detailed dimensions must be provided by the user;

3.2.8. Take-up bobbin size: Φ1000mm

3.3.8. Power:

(1) Rotating arm power: 20HP AC induction motor (domestic famous brand)) + high-quality vector frequency converter;

(2) Take-up power: 5HP * 6P AC induction motor (domestic famous brand) + high quality vector frequency converter;

(3) Displacement power: 1HP / 1:10 reduction motor (imported from Taiwan) + high quality vector frequency converter;

3.3.9 Shaft installation and unloading mode: electric oil pressure pump + oil pressure cylinder. Click the button during operation, which is convenient for operation.

3.3.10 Machine brake mode: pneumatic disc brake is adopted.

3.3 Electric control system:

3.3.1 Microcomputer man - machine interface control is adopted Automatic calculation and control of twist distance and row distance, using world famous Siemens

program controller, stable performance and high control precision It adopts the first brand of Weilun touch screen in Taiwan, with friendly interface, high resolution and convenient operation.

3.3.2 The machine program is designed by experienced engineers for many years and integrates multiple functions into a complete set of control system. It includes whether

to stop the machine when the wire is broken. Generally, the machine will be stopped when the wire is broken. However, in special cases, for example, when multiple conductor

bundles are assembled, there is no need to stop the machine. The machine can also choose whether to stop quickly or slowly in the man-machine interface, In addition, whether

to brake and stop the machine after the meter number arrives. The machine part has quite complete protection functions. The machine can not be started if the shield door of

the machine is not closed. If the door is opened incorrectly during operation, the machine will immediately brake and stop. The pallet lifting table cannot be started until it falls

to the bottom, so as to prevent other accessories from being hit during the operation of the swivel arm. There are protection switches on the left and right of the take-up travel car,

The machine will stop automatically when it encounters the protection switch at the left and right limits. There are Chinese prompts in the touch screen in case of misoperation

and fault of the machine. Press the prompts to release the alarm

3.3.3 Low voltage electrical appliances of electric control system are famous brands such as Schneider of France, PLC: Siemens, Touch screen:Weilun, Frequency converter: Inovance.

3.3.4 Machine total length: 15 meters.

4.Other

4.1. The total power consumption of the machine is about 22KW. The power supply is required to be three-phase five wire system 380V.50Hz.

4.2. The air pressure required by the machine is 5kg

4.3. Machine routing direction:

4.4. Machine paint color: Customized.

Ningbo Capstian Technology Co.,Ltd.

Ningbo Capstian Technology Co.,Ltd.